-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Featured Blogs

The Art of Consistent Grinding

Consistency in grind size is paramount for optimal extraction. Uneven grinds lead to a chaotic extraction process, resulting in a bitter, sour, or otherwise unbalanced cup. Manual grinders, when properly used, allow for exceptional control over grind size. Unlike electric grinders, which may struggle with consistency across the entire batch, especially with burr grinders of inferior quality, a well-maintained hand grinder enables the user to achieve a remarkably uniform grind. This is achieved through a combination of factors, including the quality of the burrs, the user's technique, and the type of beans being ground.

The burr set within the grinder is the heart of the process. Conical burrs, known for their consistent grind size and durability, are preferred by many manual grinding enthusiasts. Flat burrs, while capable of producing excellent results, often require more skill and experience to maintain optimal consistency. The user's technique, specifically the consistency of the turning motion and the applied pressure, significantly impacts the final grind. Practice is key to developing the muscle memory necessary for consistent grinding. Regular cleaning and maintenance of the grinder also play crucial roles, ensuring that the burrs remain sharp and free from coffee grounds that could affect their performance and introduce inconsistencies.

Unlocking the Bean's Potential

The type of bean and its roast level significantly affect the optimal grind size. Lighter roasts, with their more delicate structure, require a finer grind to achieve proper extraction, while darker roasts, often denser and more robust, require a coarser grind. Manual grinding allows for the nuanced adjustments necessary to cater to these variables. The ability to tailor the grind size to each specific bean and roast level unlocks a whole new dimension of flavor profiles, leading to a richer and more nuanced cup of coffee.

Beyond grind size, the act of manual grinding itself contributes to the overall coffee experience. The aroma released during the grinding process is a sensory experience that many find enriching. The slow, deliberate motion of grinding allows for a moment of mindfulness and connection with the beans, enhancing the overall appreciation of the craft of coffee making. This connection allows for greater appreciation of the subtle nuances and unique characteristics of each bean. The ritualistic aspect, combined with the ability to control every aspect of the process, turns the preparation of coffee into a meditative and enjoyable experience.

Beyond the Grind: The Complete Picture

While achieving a consistent grind is crucial, it's only one piece of the puzzle. The quality of the beans themselves, the water used, and the brewing method all play equally important roles in the final outcome. However, with consistent and precisely controlled grinding achieved using a manual grinder, you establish a solid foundation for a superior brew. The combination of careful selection of beans, precise water parameters, and the appropriate brewing technique, all built upon the foundation of a consistent manual grind, guarantees a truly exceptional coffee experience.

In conclusion, the pursuit of the perfect cup of coffee is a journey of exploration and refinement. Manual grinding is not just a step in the process; it’s an art form that elevates the entire coffee experience. It empowers the user to take control, fostering an intimate connection with the beans and unlocking the full spectrum of flavors they have to offer. From bean to cup, manual grinding is the key to achieving consistent grinds and unparalleled coffee flavor.

-

High Salt Spray Kodest Electrophoresis

High salt spray Kodest electrophoresis is a specialized electrochemical technique used for accelerated corrosion testing, offering insights into the durability and protective properties of coatings. Understanding its behavior is crucial for various industries, from automotive to aerospace, where material longevity is paramount.Enhanced Sensitivity

This method leverages a highly saline environment to aggressively simulate real-world corrosive conditions. The increased salt concentration accelerates the corrosion process, significantly reducing testing time compared to natural weathering. This expedited process allows for quicker material assessment and facilitates faster product development cycles.

Kodest Electrophoresis Application

Kodest electrophoresis, a type of electrodeposition process, is often employed in conjunction with the salt spray test. This ensures a uniform and tightly bound coating, providing superior corrosion resistance. The precise control offered by Kodest electrophoresis makes it ideal for creating consistent, high-quality coatings for reliable testing results.

Data Interpretation and Analysis

The results of high salt spray Kodest electrophoresis testing are analyzed by assessing the extent and nature of corrosion. Factors like blister formation, cracking, and rust propagation are carefully observed and quantified. This detailed analysis provides valuable data for optimizing coating formulations and predicting long-term performance in diverse environments.

Advantages and Limitations

The accelerated nature of the test is a major advantage, offering cost and time savings. However, it's crucial to remember the accelerated nature of the test might not perfectly replicate real-world conditions. Results should be interpreted cautiously and ideally correlated with other real-world exposure data for complete product assessment.

2025-04-17dgkede -

Discover the perfect fit. That's the promise of custom-designed activewear, and it's a promise worth exploring. For years, athletes and fitness enthusiasts have been limited to off-the-rack clothing, often settling for ill-fitting garments that compromise comfort and performance. But the rise of personalized apparel is changing the game, offering a solution that prioritizes both style and functionality. This article delves into the world of custom-designed activewear, specifically focusing on yoga, fitness, and beyond, highlighting how personalized style can unleash your inner athlete.

Discover the perfect fit. That's the promise of custom-designed activewear, and it's a promise worth exploring. For years, athletes and fitness enthusiasts have been limited to off-the-rack clothing, often settling for ill-fitting garments that compromise comfort and performance. But the rise of personalized apparel is changing the game, offering a solution that prioritizes both style and functionality. This article delves into the world of custom-designed activewear, specifically focusing on yoga, fitness, and beyond, highlighting how personalized style can unleash your inner athlete.The Advantages of Custom Activewear

The benefits of custom-designed activewear extend far beyond simply looking good. While aesthetic appeal is undoubtedly a significant factor, the true advantages lie in performance and comfort. Imagine activewear that molds to your body like a second skin, providing unrestricted movement and unwavering support. This level of precision is impossible to achieve with mass-produced clothing. Custom-designed pieces consider your unique body measurements, ensuring a perfect fit that minimizes chafing, prevents slippage, and optimizes performance.

Furthermore, custom activewear allows for personalized material selection. Different fabrics offer varied levels of breathability, moisture-wicking, and compression. By choosing the materials that best suit your needs and preferences, you can create garments perfectly tailored to your workout routine and climate conditions. Whether you prefer lightweight fabrics for hot yoga sessions or thicker, more supportive materials for weight training, the possibilities are endless.

Beyond the physical benefits, there's also a psychological boost that comes with wearing custom-designed activewear. Feeling confident and comfortable in your clothing can significantly impact your performance and overall workout experience. When you look good, you feel good, and that translates to a more positive and productive workout.

Design Options for Yoga and Fitness

Custom activewear offers unparalleled freedom in design. For yoga enthusiasts, this means choosing fabrics that offer exceptional flexibility and breathability, allowing for effortless movement through various poses. Consider lightweight, moisture-wicking materials like bamboo or recycled polyester, often favored for their eco-friendly qualities and comfortable feel against the skin. Design details can be customized to enhance the yoga experience, incorporating subtle features like strategically placed seams to prevent restriction or comfortable, wide waistband designs for support and comfort.

For those focused on fitness, the possibilities are equally expansive. High-performance fabrics like nylon and spandex offer excellent compression and support for high-impact activities like running or weightlifting. Custom designs can incorporate features like strategically placed pockets for small essentials, reflective elements for safety during outdoor workouts, or custom-designed compression panels to target specific muscle groups.

Beyond specific activities, custom designs can also incorporate personal touches that reflect individual style. This could involve adding personalized logos, inspirational quotes, or unique patterns and colors. The ability to personalize your activewear reflects your individuality, creating a sense of ownership and pride in your fitness journey.

Beyond the Workout: Everyday Wearability

The versatility of custom-designed activewear extends beyond the gym or yoga studio. Many find that the comfort and style of their custom pieces make them ideal for everyday wear. The sleek designs and high-quality materials translate seamlessly from workout to errands, creating a wardrobe that is both functional and fashionable.

This aspect of custom activewear allows for a more streamlined and efficient wardrobe. By investing in high-quality, versatile pieces that can be worn for multiple occasions, you can minimize the need for a large number of clothes, promoting a more sustainable and practical approach to fashion.

The Process of Designing Your Custom Activewear

Creating your own custom activewear is typically a straightforward process. Many companies offer online design tools and consultations that guide you through each step, from selecting fabrics and choosing colors to adding personal touches and finalizing your measurements. High-quality images and detailed measurement guides make it easy to achieve the desired outcome, ensuring a perfect fit and a design that perfectly captures your vision.

This personalized approach allows for adjustments and feedback throughout the process. This collaborative approach ensures the final product accurately reflects your preferences and needs, minimizing any potential disappointments. The commitment to providing excellent customer service further enhances the overall experience, transforming the process of acquiring custom activewear into an enjoyable and empowering journey.

Unleashing Your Inner Athlete

Ultimately, custom-designed activewear is more than just clothing; it's an investment in yourself and your fitness journey. By prioritizing comfort, performance, and personal style, you're creating a supportive environment that encourages you to push your boundaries and achieve your fitness goals. The confidence that comes with wearing clothes that perfectly fit and reflect your individuality is an invaluable asset, empowering you to unleash your inner athlete and embrace your fitness journey with renewed enthusiasm.

The ability to personalize your activewear allows you to connect with your workout on a deeper level. It’s about more than just the physical activity; it's about embracing a lifestyle that prioritizes health, well-being, and self-expression. Custom activewear provides the perfect platform to express your unique style, fostering a stronger sense of self and driving you towards greater achievements.

2025-04-30dgruisha -

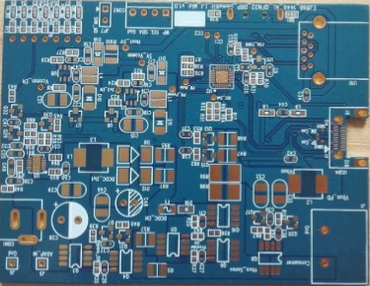

The relentless pursuit of higher speeds and increased data density in modern electronic devices necessitates sophisticated signal integrity management. High-performance multilayer PCBs (printed circuit boards) are at the heart of this challenge, demanding precise control over impedance to ensure reliable signal transmission and minimize electromagnetic interference (EMI) and electromagnetic susceptibility (EMS). This article explores a high-performance multilayer PCB impedance control EMS solution, highlighting its key features and benefits in mitigating these critical design concerns.

The relentless pursuit of higher speeds and increased data density in modern electronic devices necessitates sophisticated signal integrity management. High-performance multilayer PCBs (printed circuit boards) are at the heart of this challenge, demanding precise control over impedance to ensure reliable signal transmission and minimize electromagnetic interference (EMI) and electromagnetic susceptibility (EMS). This article explores a high-performance multilayer PCB impedance control EMS solution, highlighting its key features and benefits in mitigating these critical design concerns.Precise Impedance Control through Layer Stackup Optimization

A core aspect of this solution lies in the meticulous design of the PCB layer stackup. Careful selection of dielectric materials, conductor thicknesses, and the arrangement of signal layers, power planes, and ground planes are crucial for achieving the target impedance. Advanced simulation tools are employed to model the electromagnetic behavior of the PCB stackup, ensuring accurate impedance predictions before manufacturing. This predictive modeling allows for iterative refinement of the layer stackup to minimize deviations from the desired impedance value, ultimately leading to improved signal integrity.

Furthermore, the choice of dielectric material is paramount. Low-loss materials with a stable dielectric constant across a wide range of frequencies are preferred to minimize signal attenuation and distortion. The precise control of conductor thicknesses, achieved through advanced manufacturing techniques, ensures consistent impedance across the entire PCB. These factors collectively contribute to a robust and predictable impedance profile, reducing the likelihood of signal reflections and crosstalk.

Effective EMI/EMS Shielding Strategies

Electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) are significant concerns in high-speed digital systems. This solution incorporates various shielding strategies to mitigate these issues. The strategic placement of ground planes and power planes within the multilayer stackup acts as an effective shield, reducing the radiation of electromagnetic energy from the signal traces. Continuous ground planes, free from discontinuities and vias, offer optimal shielding performance.

Additionally, the use of conductive shielding layers, such as copper foils, further enhances EMI/EMS protection. These shielding layers can be strategically placed to enclose sensitive signal traces, effectively isolating them from external electromagnetic fields. Careful consideration is given to the continuity of these shielding layers to avoid creating openings that could compromise shielding effectiveness. Proper grounding of these shields is critical to their effectiveness.

Advanced Simulation and Verification Techniques

To guarantee the success of the impedance control and EMS solution, advanced simulation and verification techniques are employed throughout the design process. High-frequency electromagnetic simulation software is used to predict the electromagnetic behavior of the PCB, allowing designers to identify and address potential issues before manufacturing. This predictive capability significantly reduces the risk of costly redesigns and delays.

Furthermore, rigorous testing and verification are carried out on the final PCB. Measurements of impedance, return loss, insertion loss, and other relevant parameters are performed to ensure that the design meets the specified requirements. These measurements confirm the effectiveness of the impedance control and EMS strategies implemented, providing confidence in the reliability and performance of the final product.

Conclusion

The high-performance multilayer PCB impedance control EMS solution presented here represents a comprehensive approach to managing signal integrity and mitigating EMI/EMS issues in high-speed electronic devices. Through meticulous layer stackup optimization, effective shielding strategies, and rigorous simulation and verification, this solution ensures reliable signal transmission and enhances the overall performance and robustness of the final product. This holistic approach is essential for meeting the increasingly stringent requirements of modern electronic systems.

2025-05-24szshuoqiang -

Lightweight Flat Flexible Cables for Military Avionics PCBs

In the demanding world of military avionics, where every gram and millimeter counts, the need for reliable, lightweight, and flexible solutions is paramount. Lightweight Flat Flexible Cables (FFCs) have emerged as a game-changer for Printed Circuit Boards (PCBs) in military applications. These cables offer a unique combination of durability, flexibility, and weight savings, making them ideal for the harsh environments and tight spaces typical of avionics systems. As military technology advances, the demand for more efficient and compact wiring solutions grows, and FFCs are stepping up to meet these challenges.

The use of FFCs in military avionics is not just about reducing weight; it’s about enhancing performance, reliability, and maintainability. Traditional wiring harnesses are bulky and rigid, often complicating installation and maintenance. In contrast, FFCs provide a sleek, streamlined alternative that can withstand extreme temperatures, vibrations, and electromagnetic interference. This article delves into the various aspects of FFCs, exploring their benefits, materials, design considerations, and applications in military avionics.

Benefits of Lightweight Flat Flexible Cables

One of the most significant advantages of FFCs is their weight reduction compared to conventional wiring. In military aircraft, every ounce saved translates to improved fuel efficiency and payload capacity. FFCs are incredibly thin and lightweight, yet they maintain high conductivity and durability. This makes them perfect for avionics systems where space and weight are at a premium.

Another key benefit is their flexibility. Unlike rigid cables, FFCs can bend and twist without compromising performance. This flexibility allows for easier routing around tight corners and through confined spaces, reducing the risk of damage during installation or operation. Additionally, FFCs are less prone to wear and tear, ensuring longer service life and lower maintenance costs.

Materials and Construction

The materials used in FFCs are carefully selected to meet the rigorous demands of military avionics. Typically, these cables consist of thin layers of conductive material, such as copper, sandwiched between insulating layers of polyimide or polyester. These materials offer excellent thermal stability, chemical resistance, and mechanical strength, ensuring reliable performance in extreme conditions.

The construction of FFCs also plays a crucial role in their performance. The conductive traces are often arranged in a flat, ribbon-like configuration, which minimizes signal interference and crosstalk. This design is particularly important in avionics, where signal integrity is critical for communication and navigation systems. Advanced manufacturing techniques, such as precision etching and laser cutting, ensure that FFCs meet the exacting standards required for military applications.

Design Considerations

When designing FFCs for military avionics, several factors must be taken into account. First and foremost is the environmental conditions the cables will face. Military aircraft operate in a wide range of temperatures, from sub-zero altitudes to scorching desert environments. FFCs must be designed to withstand these extremes without degrading in performance.

Another critical consideration is electromagnetic interference (EMI). Avionics systems are highly sensitive to EMI, which can disrupt signals and cause malfunctions. FFCs are often shielded with conductive layers or coatings to minimize EMI and ensure reliable operation. Additionally, the cables must be designed to resist vibrations and mechanical stress, which are common in military aircraft.

Applications in Military Avionics

FFCs are used in a variety of military avionics applications, from cockpit displays to radar systems. Their lightweight and flexible nature makes them ideal for use in tight spaces, such as behind instrument panels or within wing assemblies. They are also commonly used in communication systems, where signal integrity is paramount.

One notable application is in unmanned aerial vehicles (UAVs), where weight and space constraints are even more critical. FFCs enable the compact and efficient wiring needed for these advanced systems, ensuring reliable performance in the field. As military technology continues to evolve, the role of FFCs in avionics is expected to grow, driving further innovations in their design and functionality.

In conclusion, Lightweight Flat Flexible Cables are revolutionizing military avionics by offering a perfect blend of weight savings, flexibility, and reliability. Their advanced materials and construction make them well-suited for the harsh conditions of military operations, while their design versatility ensures they can meet the evolving needs of modern avionics systems. As the demand for more efficient and compact wiring solutions increases, FFCs will undoubtedly play a pivotal role in shaping the future of military technology.

2025-08-09szshuoqiang

Latest Blogs

Discover the Future of HDI Manufacturing 4 Layer Focus

Advancements in Manufacturing Processes

The creation of high-quality 4-layer HDI boards relies heavily on precision and automation. Recent advancements in laser direct imaging (LDI) technology have significantly improved the accuracy and speed of creating intricate circuitry. This allows for finer lines and spaces, enabling greater miniaturization and component density on the board. Furthermore, the incorporation of advanced materials, such as low-temperature co-fired ceramics (LTCC) and build-up films, contributes to improved signal integrity and thermal management, crucial for high-performance applications.

Automated optical inspection (AOI) systems have become indispensable in ensuring quality control throughout the manufacturing process. These systems can detect even minute defects, such as missing vias or solder bridging, ensuring a high yield rate and reducing the likelihood of costly rework or product failure. The integration of AI and machine learning into AOI systems further enhances their capabilities, allowing for faster and more accurate defect detection and classification.

Material Innovations and Their Impact

The materials used in HDI manufacturing are continuously evolving to meet the demands of increasingly complex applications. The development of new dielectric materials with lower dielectric constants allows for higher signal speeds and reduced signal loss. This is particularly important for high-frequency applications, such as 5G communication devices and high-speed data centers.

The use of embedded components, such as passive components and even active chips directly integrated into the HDI substrate, is gaining traction. This technology, known as embedded passive devices (EPDs) and embedded system-in-package (SiP), further reduces the overall size and complexity of electronic devices, while improving reliability and reducing assembly costs. The integration of these advanced materials requires sophisticated manufacturing techniques, pushing the boundaries of current capabilities.

The Role of Design for Manufacturing (DFM)

Effective design for manufacturing (DFM) is paramount in ensuring the successful production of complex 4-layer HDI boards. DFM principles consider the manufacturing process from the initial design stage, optimizing the design to minimize production challenges and maximize yield. This involves careful consideration of factors like via placement, trace routing, and component placement to avoid manufacturing limitations and ensure electrical performance.

Collaboration between designers and manufacturers is crucial for effective DFM. The early engagement of manufacturing experts in the design process allows for the identification and mitigation of potential issues early on, reducing the risk of costly revisions and delays in production. The utilization of simulation software allows for the virtual prototyping and testing of designs, further optimizing the manufacturability of HDI boards.

Future Trends and Challenges

Looking ahead, the future of 4-layer HDI manufacturing is likely to be shaped by several key trends. The ongoing miniaturization of electronic devices will continue to drive the demand for ever-finer lines and spaces on HDI boards. This will require further advancements in manufacturing technologies and materials.

Challenges remain, however. The increasing complexity of HDI boards necessitates more sophisticated testing and inspection methods. Ensuring the reliability and durability of these highly integrated boards under diverse operating conditions is also critical. Overcoming these challenges will require ongoing research and development efforts, collaborations across the industry, and a continued focus on innovation.

Explore the Cutting Edge 4 Layer HDI Manufacturing Plant

Advanced Substrate Materials and Preparation

The foundation of any high-quality HDI board lies in the selection and preparation of the substrate material. Typically, this involves high-quality FR-4 epoxy glass, chosen for its balance of thermal stability, mechanical strength, and dielectric properties. The plant utilizes advanced laser drilling techniques to create precisely sized vias, ensuring flawless alignment and connectivity between layers. This process requires meticulous control of laser power, pulse width, and beam focus to prevent damage to the surrounding material and maintain the integrity of the substrate. Furthermore, surface treatment processes, such as copper plating, are employed to enhance the adhesion of subsequent layers and ensure optimal electrical conductivity.

A crucial step involves the careful cleaning and preparation of the substrate surface before each subsequent layer is added. This minimizes any contaminants that could interfere with the bonding process and ultimately impact the board's performance and reliability. The cleanliness standards employed in this facility are exceptionally high, frequently involving multi-stage cleaning processes, utilizing various chemical solvents and specialized cleaning equipment, to achieve the necessary level of purity.

Microscopic Precision in Layer Construction

The construction of the four layers involves several intricate steps. The plant utilizes advanced photolithography techniques to precisely pattern the copper circuitry on each layer. This requires high-resolution photomasks and sophisticated alignment systems to ensure accurate registration between layers. Any misalignment can lead to short circuits or open circuits, rendering the board unusable. The photoresist application, exposure, and development processes are critically controlled to achieve the finest line widths and spaces, often measuring in microns. This level of precision is paramount for achieving the high density characteristic of HDI technology.

After photolithography, the copper is etched using precise chemical processes to remove the unwanted copper, leaving behind only the desired circuitry. This etching process is monitored meticulously to ensure consistent results and prevent over-etching, which could damage the delicate circuitry. Subsequent steps involve the electroplating of copper to build up the thickness of the conductive traces, ensuring the required electrical current carrying capacity.

Automated Assembly and Inspection

The assembly and inspection processes in a cutting-edge 4-layer HDI manufacturing plant are highly automated. Advanced robotic systems handle the intricate tasks of placing components, soldering connections, and aligning layers with incredible precision. Automated optical inspection (AOI) systems are employed at every stage of the manufacturing process to detect any defects or irregularities. These systems can identify flaws as small as a few micrometers, ensuring the high quality and reliability of the final product. This reduces human error and significantly increases throughput.

Further quality control includes electrical testing to verify the functionality of the completed circuit board. This involves applying various electrical signals and measuring the responses to detect any shorts, opens, or other electrical anomalies. This final quality assurance ensures only boards meeting stringent specifications leave the facility. This dedication to quality control underscores the critical role these HDI boards play in the performance of modern electronic devices.

Challenges and Future Trends

Manufacturing 4-layer HDI boards presents several challenges, including maintaining tight tolerances, minimizing defects, and managing the complexity of the manufacturing process. The ongoing miniaturization trend in electronics demands even higher density interconnects, pushing the boundaries of current manufacturing techniques. The industry continues to explore new materials, processes, and automation technologies to meet these ever-increasing demands.

Future trends in 4-layer HDI manufacturing include the increased adoption of additive manufacturing techniques, improved materials with enhanced thermal and electrical properties, and the development of more sophisticated automation and inspection systems. The pursuit of higher density, better performance, and improved cost-effectiveness will continue to drive innovation in this critical sector of electronics manufacturing.

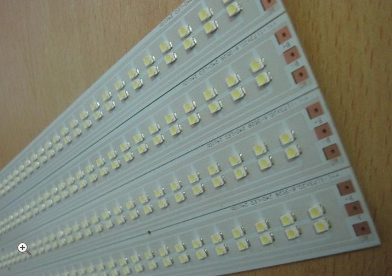

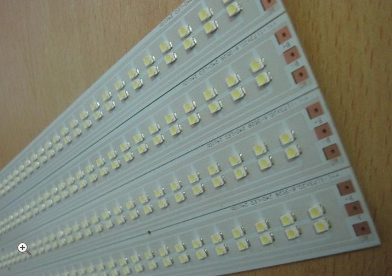

Advanced LED PCB MCPCB Thermal Management

Material Selection and Design

The foundation of effective thermal management lies in the careful selection of materials. High-thermal-conductivity substrates, such as aluminum nitride (AlN) or aluminum oxide (Al2O3), offer significantly improved heat dissipation compared to traditional FR4 PCBs. The thickness of the MCPCB also plays a vital role; thicker substrates provide a larger heat-spreading area and reduce thermal resistance. Furthermore, the design of the copper traces on the MCPCB itself is crucial. Wide, thick traces minimize resistance to current flow, reducing Joule heating, while strategically placed thermal vias connect the LED junction to the MCPCB's heat sink interface for efficient heat transfer.

Beyond the MCPCB itself, careful consideration must be given to the thermal interface materials (TIMs) used between the LED and the MCPCB, and between the MCPCB and the heat sink. These TIMs must possess high thermal conductivity and a low thermal impedance to effectively transfer heat. Common choices include thermal grease, thermal pads, and phase-change materials, each with its own advantages and disadvantages depending on the specific application requirements.

Heat Sink Design and Integration

Even with an optimally designed MCPCB, effective heat dissipation necessitates a well-designed heat sink. The size and type of heat sink must be carefully selected based on the power dissipation of the LEDs and the ambient operating temperature. Finned heat sinks, for instance, offer a large surface area for convective cooling, while heat pipes can efficiently transfer heat over larger distances. The surface finish of the heat sink, whether anodized or coated, can also impact its effectiveness.

The mechanical integration of the MCPCB and heat sink is equally important. A strong and thermally conductive connection is essential to minimize thermal resistance at the interface. Pressure-sensitive adhesives, screws, or a combination of both can be used to achieve a secure and thermally efficient connection. The design should also account for thermal expansion mismatch between the MCPCB and the heat sink to prevent stress and potential damage.

Advanced Cooling Techniques

For high-power LED applications with demanding thermal requirements, advanced cooling techniques may be necessary. These can include liquid cooling, which offers significantly higher heat transfer capabilities than air cooling, or the use of thermoelectric coolers (TECs) to actively manage the temperature of the LED junction. These approaches are generally more complex and expensive but can be critical for applications where passive cooling is insufficient.

Moreover, computational fluid dynamics (CFD) simulations are increasingly used in the design process to optimize heat dissipation. CFD allows engineers to visualize and analyze airflow patterns and temperature distributions, enabling them to fine-tune the design of the MCPCB, heat sink, and cooling system for optimal performance. This predictive capability minimizes the need for extensive prototyping and accelerates the development process.

Thermal Management Strategies and Testing

A holistic approach to thermal management requires consideration of all aspects—material selection, design, and cooling techniques—working in concert. Proper thermal design needs to start early in the product development lifecycle, ideally integrating thermal simulations and analysis throughout the process. Regular thermal testing, using methods like infrared thermography, is essential to validate the effectiveness of the chosen strategy and ensure the LED system operates within its specified temperature limits, maintaining reliability and extending its lifespan.

In conclusion, advanced thermal management for LED MCPCBs is a multifaceted engineering challenge that requires a comprehensive understanding of materials science, heat transfer principles, and design optimization. By employing a holistic strategy incorporating advanced materials, effective heat sinks, and sophisticated cooling techniques, designers can ensure that their high-power LED applications achieve optimal performance and longevity.

Superior LED MCPCB Design and Manufacturing

Thermal Management: The Cornerstone of Superior MCPCB Design

Efficient heat dissipation is arguably the most critical aspect of MCPCB design. LEDs generate significant heat during operation, and excessive temperatures can drastically reduce their lifespan and luminous efficacy. Superior MCPCB designs employ advanced thermal management techniques, such as optimized copper thicknesses, strategically placed heat sinks, and the use of high-thermal-conductivity materials like aluminum nitride or aluminum oxide substrates. These elements work in concert to rapidly draw heat away from the LED die, preventing overheating and ensuring consistent performance.

Furthermore, sophisticated thermal simulations are employed during the design phase to predict and optimize heat flow paths within the MCPCB. This allows engineers to fine-tune the design, minimizing thermal resistance and maximizing heat transfer efficiency. The result is a longer-lasting, more reliable LED system that maintains its brightness and color consistency over its operational lifetime.

Material Selection: Optimizing Performance and Durability

The choice of materials significantly impacts the performance and longevity of an MCPCB. Superior designs utilize high-quality materials selected for their specific properties. The substrate material, typically aluminum or aluminum nitride, needs to possess high thermal conductivity to efficiently dissipate heat. The copper layers, forming the circuit traces, must have excellent conductivity and adhesion to ensure reliable electrical connections. Furthermore, the solder used for mounting the LEDs must be compatible with the substrate and LED components, providing a robust and long-lasting bond.

Beyond the core materials, the selection of protective coatings and encapsulants plays a crucial role in enhancing the MCPCB's durability and resistance to environmental factors. These coatings offer protection against moisture, corrosion, and other potential contaminants, extending the lifespan of the entire system under various operating conditions.

Manufacturing Precision: Ensuring Consistent Quality

Superior MCPCB manufacturing relies on highly precise and automated processes. Advanced techniques such as laser drilling, high-precision screen printing, and automated placement and soldering are essential for achieving consistent quality and minimizing defects. These processes ensure accurate placement of components, uniform solder joints, and consistent circuit trace dimensions, all contributing to optimal performance and reliability.

Rigorous quality control measures are integrated throughout the manufacturing process. This includes regular inspections, testing, and analysis to guarantee that the MCPCBs meet the specified performance standards. These quality control procedures not only ensure the quality of individual MCPCBs but also provide valuable feedback for continuous improvement and optimization of the manufacturing processes.

Design for Manufacturing (DFM): Streamlining Production and Reducing Costs

Implementing Design for Manufacturing (DFM) principles from the initial design phase is vital for producing high-quality MCPCBs efficiently and cost-effectively. This involves considering the manufacturability of the design, selecting readily available components, and avoiding complex or difficult-to-assemble features. DFM streamlines the production process, reduces waste, and ultimately lowers the overall cost of the MCPCB.

By carefully considering all these aspects – from thermal management and material selection to manufacturing precision and DFM principles – superior LED MCPCB design and manufacturing deliver exceptional performance, extended lifespan, and improved cost-effectiveness, ultimately driving innovation in the LED lighting industry.

The Future of Electronic Circuit Design Trends in PCB Technology

The world of electronic circuit design is undergoing a transformative phase, driven by rapid advancements in technology and evolving industry demands. Printed Circuit Board (PCB) technology, the backbone of modern electronics, is at the heart of this revolution. As devices become smaller, smarter, and more interconnected, the future of PCB design is poised to embrace innovative trends that will redefine how we create and interact with electronic systems. From flexible and high-density interconnects to sustainable materials and AI-driven design tools, the landscape of PCB technology is evolving at an unprecedented pace. This article explores the key trends shaping the future of electronic circuit design, offering insights into what lies ahead for engineers, designers, and manufacturers.

Miniaturization and High-Density Interconnects

The demand for smaller and more powerful electronic devices continues to push the boundaries of PCB design. Miniaturization is no longer a luxury but a necessity, especially in industries like consumer electronics, medical devices, and aerospace. High-density interconnect (HDI) technology is at the forefront of this trend, enabling designers to pack more functionality into smaller spaces. HDI PCBs feature finer lines, smaller vias, and multiple layers, allowing for improved signal integrity and reduced power consumption.

Moreover, the rise of 5G and IoT devices has further accelerated the need for compact and efficient PCB designs. As components shrink and performance requirements grow, designers must adopt advanced techniques like embedded components and microvia technology. These innovations not only enhance the performance of electronic devices but also open new possibilities for applications in wearables, smart sensors, and autonomous systems.

Flexible and Stretchable PCBs

Traditional rigid PCBs are giving way to flexible and stretchable alternatives, thanks to advancements in materials science and manufacturing techniques. Flexible PCBs (FPCBs) are now widely used in applications where space constraints and mechanical flexibility are critical, such as foldable smartphones, wearable health monitors, and automotive electronics. These PCBs can bend, twist, and conform to irregular shapes, offering unparalleled design freedom.

Looking ahead, stretchable PCBs are emerging as the next frontier. These circuits can elongate and recover without losing functionality, making them ideal for applications like soft robotics, biomedical implants, and smart textiles. Researchers are exploring novel materials, such as conductive polymers and liquid metals, to create circuits that can withstand extreme deformations. As these technologies mature, they will unlock new possibilities for electronics that seamlessly integrate with the human body and the environment.

Sustainability and Eco-Friendly Materials

The electronics industry is increasingly focusing on sustainability, and PCB design is no exception. Traditional PCBs often rely on hazardous materials like lead and brominated flame retardants, which pose environmental and health risks. In response, the industry is shifting toward eco-friendly alternatives, such as halogen-free substrates and biodegradable materials.

Additionally, the concept of circular economy is gaining traction in PCB manufacturing. Companies are exploring ways to recycle and reuse PCB materials, reducing electronic waste and conserving resources. Innovations like additive manufacturing (3D printing) are also being leveraged to minimize material waste during production. As regulatory pressures and consumer demand for green products grow, sustainable PCB design will become a cornerstone of the industry's future.

AI and Automation in PCB Design

Artificial intelligence (AI) and machine learning are revolutionizing the way PCBs are designed and manufactured. AI-powered design tools can automate complex tasks, such as component placement and routing, significantly reducing development time and human error. These tools leverage vast datasets to optimize designs for performance, cost, and manufacturability, enabling engineers to focus on innovation rather than repetitive tasks.

Beyond design, AI is also transforming PCB testing and quality control. Machine learning algorithms can detect defects and predict failures with high accuracy, ensuring reliable and high-quality products. As AI continues to evolve, it will enable fully autonomous design workflows, where systems can self-optimize and adapt to changing requirements in real time. This paradigm shift will democratize PCB design, making it accessible to a broader range of innovators.

Advanced Materials and Thermal Management

As electronic devices become more powerful, managing heat dissipation is a growing challenge. Traditional materials like FR-4 are often inadequate for high-performance applications, leading to the adoption of advanced substrates such as ceramic-filled laminates and metal-core PCBs. These materials offer superior thermal conductivity, ensuring stable operation even under extreme conditions.

Furthermore, the integration of nanomaterials, like graphene and carbon nanotubes, is poised to revolutionize PCB technology. These materials exhibit exceptional electrical and thermal properties, enabling faster signal transmission and more efficient heat dissipation. Researchers are also exploring self-healing materials that can repair minor damages autonomously, extending the lifespan of electronic devices. The future of PCB design will rely heavily on these cutting-edge materials to meet the demands of next-generation electronics.

Mastering Signal Integrity in Electronic Circuit Design for PCBs

Signal integrity is a critical aspect of electronic circuit design, especially in the realm of printed circuit boards (PCBs). As electronic devices become faster and more complex, maintaining signal integrity has become a paramount concern for engineers and designers. Mastering Signal Integrity in Electronic Circuit Design for PCBs is not just about ensuring that signals reach their destinations; it’s about guaranteeing that they do so without distortion, noise, or timing issues that could compromise the performance of the entire system.

In today’s high-speed digital world, signals are often transmitted at frequencies where even minor imperfections in the PCB layout can lead to significant problems. Reflections, crosstalk, and electromagnetic interference (EMI) are just a few of the challenges that designers face. Understanding and addressing these issues is essential for creating reliable and efficient electronic systems. This article delves into the key aspects of mastering signal integrity, offering insights and practical advice for PCB designers.

Understanding Signal Integrity Fundamentals

Signal integrity refers to the quality of an electrical signal as it travels through a PCB. At high frequencies, signals are more susceptible to degradation due to various factors such as impedance mismatches, parasitic capacitance, and inductance. A solid grasp of these fundamentals is the first step toward mastering signal integrity.

One of the primary concepts in signal integrity is impedance matching. When the impedance of the transmission line does not match the impedance of the source or load, reflections occur, leading to signal distortion. Properly designing transmission lines with controlled impedance is crucial to minimize these reflections. Tools like time-domain reflectometry (TDR) can help designers measure and adjust impedance in their PCB layouts.

Managing Crosstalk and EMI

Crosstalk is another major concern in PCB design. It occurs when signals from one trace interfere with adjacent traces, leading to unwanted noise and signal corruption. To mitigate crosstalk, designers must pay attention to trace spacing, routing techniques, and the use of ground planes. Differential signaling is also an effective method to reduce crosstalk, as it relies on paired traces that carry equal and opposite signals.

Electromagnetic interference (EMI) is closely related to crosstalk and can arise from both internal and external sources. Proper shielding, careful component placement, and the use of filters can help minimize EMI. Additionally, adhering to design guidelines such as avoiding sharp bends in traces and maintaining consistent trace widths can further reduce EMI risks.

Power Integrity and Its Impact on Signal Integrity

Power integrity is often overlooked but is intrinsically linked to signal integrity. Fluctuations in the power supply can introduce noise into the signal paths, leading to performance issues. Decoupling capacitors play a vital role in stabilizing the power supply by filtering out high-frequency noise.

Another critical aspect is the design of the power distribution network (PDN). A well-designed PDN ensures that all components receive a stable voltage, reducing the likelihood of signal integrity problems. Simulation tools can help designers analyze and optimize the PDN before fabrication, saving time and costs in the long run.

Advanced Techniques for High-Speed Design

As signal frequencies continue to rise, traditional design techniques may no longer suffice. High-speed design requires advanced methods such as using microstrip and stripline transmission lines, which offer better control over impedance and reduced signal loss. Additionally, designers must consider the dielectric properties of the PCB material, as these can significantly affect signal propagation.

Another advanced technique is the use of via stitching and back drilling to minimize signal reflections and losses in multilayer PCBs. These methods are particularly important in designs involving high-density interconnects (HDIs) and high-frequency applications like 5G and beyond.

Simulation and Testing for Signal Integrity

Simulation tools are indispensable for predicting and addressing signal integrity issues before the PCB is manufactured. Tools like SPICE, HyperLynx, and ADS allow designers to model signal behavior under various conditions, identifying potential problems early in the design process.

Testing is equally important. Techniques such as eye diagram analysis and bit error rate (BER) testing provide valuable insights into signal quality. By combining simulation and testing, designers can ensure that their PCBs meet the required performance standards.

Mastering signal integrity in PCB design is a multifaceted challenge that requires a deep understanding of electrical principles, careful planning, and the use of advanced tools. By addressing impedance matching, crosstalk, power integrity, and high-speed design techniques, engineers can create robust and reliable electronic systems. As technology continues to evolve, staying ahead of signal integrity challenges will be key to success in the field of electronic circuit design.

Popular Blogs

-

Looking to outfit your fishing team, stock your retail store with unique apparel, or create branded merchandise for your fishing-related business? Designing your own custom fishing hoodies and shirts offers a powerful way to build brand loyalty, promote your business, and provide your customers with high-quality, comfortable apparel. This opportunity is further enhanced by the availability of wholesale pricing and bulk discounts, making it a financially viable option for businesses of all sizes. This comprehensive guide will explore the numerous benefits and considerations involved in designing and purchasing custom fishing apparel wholesale.

Looking to outfit your fishing team, stock your retail store with unique apparel, or create branded merchandise for your fishing-related business? Designing your own custom fishing hoodies and shirts offers a powerful way to build brand loyalty, promote your business, and provide your customers with high-quality, comfortable apparel. This opportunity is further enhanced by the availability of wholesale pricing and bulk discounts, making it a financially viable option for businesses of all sizes. This comprehensive guide will explore the numerous benefits and considerations involved in designing and purchasing custom fishing apparel wholesale.The Appeal of Custom Fishing Apparel

The fishing community is passionate and dedicated. Providing them with apparel that reflects their shared love of the sport fosters a sense of belonging and strengthens brand association. Custom designs allow for unparalleled creativity. Imagine hoodies emblazoned with your company logo, witty fishing puns, or stunning depictions of popular fish species. Shirts can showcase vibrant artwork, team names, or even individual angler's nicknames. This personalized touch transforms clothing into a powerful marketing tool and a cherished item for fishing enthusiasts.

Furthermore, the quality of the apparel itself is crucial. Choosing high-quality materials, like durable cotton blends for shirts and thick, comfortable fleece for hoodies, ensures customer satisfaction and longevity. This translates to positive word-of-mouth marketing and returning customers who appreciate the quality of your branded merchandise. Investing in premium materials reflects positively on your brand, projecting an image of professionalism and commitment to quality.

Wholesale Pricing and Bulk Discounts: A Cost-Effective Solution

One of the most significant advantages of designing custom fishing apparel is the potential for cost savings through wholesale pricing and bulk discounts. Purchasing in bulk significantly reduces the per-unit cost, making it a much more affordable option than buying individual items at retail prices. This is particularly beneficial for retailers looking to stock their shelves or businesses distributing branded apparel to employees or clients.

Many suppliers offer tiered pricing, where the cost per item decreases as the order quantity increases. This allows businesses to tailor their order size to their budget and anticipated demand. Understanding these pricing structures is vital to maximizing your return on investment. Carefully analyzing sales projections and comparing pricing from different suppliers will help you determine the most cost-effective order quantity.

Beyond the direct cost savings, wholesale purchasing also reduces the administrative burden associated with managing smaller, more frequent orders. This allows businesses to focus on other aspects of their operations, increasing efficiency and productivity.

Design Options and Customization Capabilities

The design possibilities are virtually limitless when it comes to custom fishing apparel. From simple logo placements to intricate all-over prints, the level of customization is dictated by your creative vision and the capabilities of your chosen supplier. High-quality printing techniques, such as screen printing, direct-to-garment printing, and embroidery, offer diverse options for achieving your desired look and feel.

Consider the target audience when choosing your design. A youthful, energetic brand might favor bold colors and modern graphics, while a more established brand might opt for a classic, understated design. The color scheme, font selection, and overall aesthetic should align with your brand identity and resonate with your target market. Working closely with your apparel supplier to discuss design options and feasibility is crucial to achieving your vision.

Don't overlook the potential of adding unique details, like custom labels or tags, to further personalize your apparel and enhance the brand experience. These small touches can elevate the perceived value of your product and create a memorable impression on your customers.

Choosing a Reliable Supplier

Selecting a reputable supplier is paramount to the success of your custom apparel project. Research different suppliers thoroughly, comparing their pricing, production times, minimum order quantities, and customer reviews. Look for suppliers who offer a wide range of customization options, high-quality materials, and excellent customer service.

Request samples of their work to assess the quality of their printing and the feel of the garments. This will give you a tangible understanding of the product you'll be receiving and help you make an informed decision. Inquire about their production process and lead times to ensure they can meet your deadlines.

Transparency and communication are essential qualities in a reliable supplier. A reputable supplier will be upfront about their pricing, production timelines, and any potential challenges. They should also be responsive to your inquiries and provide regular updates throughout the production process.

Marketing and Sales Strategies

Once your custom fishing apparel is ready, developing a robust marketing and sales strategy is crucial to maximizing its impact. Utilize social media platforms, online marketplaces, and your website to showcase your products. High-quality product photography and compelling descriptions are key to attracting potential customers.

Collaborating with fishing influencers or bloggers can provide valuable exposure and build credibility within the fishing community. Consider offering special promotions or discounts to incentivize purchases and build brand loyalty. Participating in fishing events or trade shows can offer excellent opportunities for direct sales and brand exposure.

Regularly monitor customer feedback and adapt your marketing strategies as needed. Addressing customer concerns promptly and demonstrating a commitment to quality will build trust and encourage repeat business. Custom fishing apparel is more than just clothing; it's a powerful tool for building brand awareness, fostering community, and driving sales.

dgruisha2025-01-03 -

Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women

Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women offers a unique opportunity to delve into the world of personalized aquatic gear. Forget generic, off-the-shelf wetsuits that compromise comfort and performance. This platform allows you to design and order custom-made wetsuits tailored precisely to your body, activity, and style preferences. Whether you're a seasoned diver, a passionate surfer, or simply someone who enjoys water sports, the ability to customize your wetsuit ensures an unparalleled level of fit, function, and aesthetic appeal. This opens doors to enhanced performance, increased comfort, and a truly unique expression of your individual style. This article explores the various facets of this exciting opportunity, from design options to material selection and the benefits of choosing custom over standard wetsuits.Unleashing Design Potential: A World of Customization

The heart of Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women lies in its commitment to personalized design. Beyond simply selecting a size, you have the power to shape every aspect of your wetsuit. This extends from choosing the overall style – from sleek and minimalist designs to bold and vibrant patterns – to selecting specific features. Imagine a wetsuit perfectly mirroring your brand or showcasing your favorite artwork. This level of customization allows for truly unique creations, far beyond anything available in standard retail options.

The platform likely provides a user-friendly interface with various design tools, allowing you to experiment with different color combinations, panel layouts, and even incorporating personalized logos or text. This digital design process provides a preview of your final product, ensuring complete satisfaction before ordering. This interactive experience removes the guesswork and allows for detailed control over your final design, enabling you to create a wetsuit that is both functional and aesthetically pleasing.

Furthermore, the design options likely extend beyond simple aesthetics. You might have the ability to specify features like reinforced knees for surfers, extra padding in specific areas for kayakers, or strategically placed pockets for divers. This level of customization ensures the wetsuit is perfectly optimized for your specific needs and activities, enhancing your performance and overall experience.

Material Matters: Choosing the Right Fabric for Your Needs

The choice of material significantly impacts the performance and longevity of your wetsuit. Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women likely offers a variety of neoprene options, each with its own unique characteristics. Understanding the differences is key to selecting the ideal material for your intended use.

Thicker neoprene offers superior warmth for colder water conditions, providing crucial insulation against hypothermia. Thinner neoprene, conversely, provides increased flexibility and freedom of movement, ideal for activities like surfing or kayaking where agility is paramount. The platform will likely clearly outline the properties of each neoprene type, enabling an informed decision based on your individual needs and the typical water temperatures you'll be facing.

Beyond neoprene type, you'll likely have the option of selecting different lining materials. Some linings provide enhanced warmth, while others focus on quick-drying properties or even anti-microbial treatments to prevent odor. These subtle nuances can dramatically impact your overall comfort and experience, highlighting the importance of thoughtful material selection during the customization process.

Wholesale Advantage: Cost-Effectiveness for Businesses and Individuals

The "wholesale" aspect of Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women offers compelling advantages for both businesses and individual consumers. For businesses, such as surf shops or dive centers, the ability to order custom wetsuits in bulk with personalized branding creates a unique selling proposition and strengthens their brand identity.

This eliminates the need to stock a wide range of sizes and styles, reducing inventory costs and storage space. Instead, they can cater to individual customer requirements efficiently and offer a genuinely personalized service. This approach fosters customer loyalty and enhances their overall brand image.

Even for individual consumers, ordering in smaller quantities through a wholesale platform might offer cost savings compared to purchasing individually designed wetsuits from smaller, boutique manufacturers. The platform's economies of scale translate into potentially more affordable prices, especially for those requiring multiple wetsuits for different activities or conditions.

Beyond the Suit: Superior Customer Service and Quality Assurance

The success of a custom wetsuit experience extends beyond just the design and materials. A reputable platform like Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women should prioritize exceptional customer service and robust quality control measures. This would involve clear communication throughout the design and ordering process, detailed instructions for accurate measurements, and prompt responses to any queries.

Furthermore, a reliable platform should offer a clear warranty and return policy, ensuring customer satisfaction even after the wetsuit has been delivered. This peace of mind is crucial, especially considering the investment involved in a custom-made product. Quality assurance procedures should be in place to guarantee the use of high-quality materials and meticulous craftsmanship, resulting in a durable and long-lasting wetsuit.

In conclusion, Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women represents a significant advancement in the world of aquatic gear. By combining personalized design with wholesale pricing and a commitment to quality, this platform offers an unprecedented opportunity to acquire a wetsuit that perfectly aligns with your individual needs, style, and budget. The ability to create a truly unique and functional wetsuit underscores the power of customization in enhancing athletic performance and personal expression.

dgruisha2024-12-27 -

Streamline Your Workflow with Our Superior Cutting Machines

In today's fast-paced business environment, efficiency is paramount. Every second saved translates to increased productivity and profitability. For businesses relying on precise and consistent cutting processes, the right equipment can make all the difference. That's where our superior cutting machines come in, offering a seamless solution to streamline your workflow and elevate your operational capabilities. Whether you're in manufacturing, textiles, packaging, or any industry requiring precise cuts, our machines offer unmatched precision, speed, and reliability, ultimately boosting your bottom line. This article will delve into the key features and benefits that set our cutting machines apart and demonstrate how they can transform your operations.Unmatched Precision and Accuracy

Our cutting machines utilize advanced technologies to ensure unparalleled precision. Forget inconsistent cuts and wasted materials – our machines deliver consistently accurate results, every time. This is achieved through a combination of factors, including high-resolution digital control systems, advanced sensor technology, and robust mechanical engineering. The sophisticated software integrated into our machines allows for incredibly detailed programming, enabling you to create intricate designs and complex cuts with absolute confidence.

This precision isn't just about aesthetics; it’s about minimizing waste and maximizing material utilization. Precise cutting reduces material spoilage, leading to significant cost savings over time. It also ensures that your final products meet the highest quality standards, enhancing your brand reputation and customer satisfaction.

Enhanced Speed and Throughput

Time is money, and our cutting machines are designed to save you both. Their high-speed operation significantly increases your throughput, allowing you to process larger volumes of material in a shorter timeframe. This accelerated production translates directly to increased profitability and the ability to meet even the most demanding deadlines.

The streamlined design and efficient operation of our machines minimize downtime and maximize productivity. Intuitive interfaces and user-friendly software simplify operation, reducing the learning curve for your team and allowing them to focus on maximizing output. The robust construction ensures long-lasting performance, minimizing maintenance and interruptions to your workflow.

Flexibility and Adaptability

Our cutting machines are not one-size-fits-all solutions. They offer a high degree of flexibility, accommodating a wide range of materials and thicknesses. Whether you work with paper, fabric, leather, plastics, or composites, our machines are adaptable to your specific needs. This versatility eliminates the need for multiple machines, streamlining your production process and reducing operational complexities.

Furthermore, our machines are easily configurable to accommodate evolving requirements. Software updates and optional add-ons allow you to expand the capabilities of your machine as your business grows, ensuring a long-term return on your investment. This adaptable nature future-proofs your operations and protects your investment in years to come.

Improved Safety and Ergonomics

Safety is a top priority in any workplace, and our cutting machines are designed with safety features that protect both your operators and your products. Automated safety mechanisms and ergonomic designs minimize the risk of accidents and injuries. The intuitive controls and clear visual indicators further contribute to a safer and more efficient working environment.

Ergonomic features, such as adjustable work surfaces and comfortable operator stations, reduce strain and fatigue, improving operator well-being and productivity. A safer and more comfortable work environment leads to a more engaged and productive workforce, boosting overall efficiency and quality.

Streamlined Workflow and Increased Profitability