-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

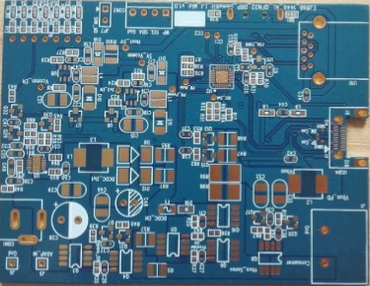

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Featured Blogs

Precise Impedance Control through Layer Stackup Optimization

A core aspect of this solution lies in the meticulous design of the PCB layer stackup. Careful selection of dielectric materials, conductor thicknesses, and the arrangement of signal layers, power planes, and ground planes are crucial for achieving the target impedance. Advanced simulation tools are employed to model the electromagnetic behavior of the PCB stackup, ensuring accurate impedance predictions before manufacturing. This predictive modeling allows for iterative refinement of the layer stackup to minimize deviations from the desired impedance value, ultimately leading to improved signal integrity.

Furthermore, the choice of dielectric material is paramount. Low-loss materials with a stable dielectric constant across a wide range of frequencies are preferred to minimize signal attenuation and distortion. The precise control of conductor thicknesses, achieved through advanced manufacturing techniques, ensures consistent impedance across the entire PCB. These factors collectively contribute to a robust and predictable impedance profile, reducing the likelihood of signal reflections and crosstalk.

Effective EMI/EMS Shielding Strategies

Electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) are significant concerns in high-speed digital systems. This solution incorporates various shielding strategies to mitigate these issues. The strategic placement of ground planes and power planes within the multilayer stackup acts as an effective shield, reducing the radiation of electromagnetic energy from the signal traces. Continuous ground planes, free from discontinuities and vias, offer optimal shielding performance.

Additionally, the use of conductive shielding layers, such as copper foils, further enhances EMI/EMS protection. These shielding layers can be strategically placed to enclose sensitive signal traces, effectively isolating them from external electromagnetic fields. Careful consideration is given to the continuity of these shielding layers to avoid creating openings that could compromise shielding effectiveness. Proper grounding of these shields is critical to their effectiveness.

Advanced Simulation and Verification Techniques

To guarantee the success of the impedance control and EMS solution, advanced simulation and verification techniques are employed throughout the design process. High-frequency electromagnetic simulation software is used to predict the electromagnetic behavior of the PCB, allowing designers to identify and address potential issues before manufacturing. This predictive capability significantly reduces the risk of costly redesigns and delays.

Furthermore, rigorous testing and verification are carried out on the final PCB. Measurements of impedance, return loss, insertion loss, and other relevant parameters are performed to ensure that the design meets the specified requirements. These measurements confirm the effectiveness of the impedance control and EMS strategies implemented, providing confidence in the reliability and performance of the final product.

Conclusion

The high-performance multilayer PCB impedance control EMS solution presented here represents a comprehensive approach to managing signal integrity and mitigating EMI/EMS issues in high-speed electronic devices. Through meticulous layer stackup optimization, effective shielding strategies, and rigorous simulation and verification, this solution ensures reliable signal transmission and enhances the overall performance and robustness of the final product. This holistic approach is essential for meeting the increasingly stringent requirements of modern electronic systems.

-

Lightweight Flat Flexible Cables for Military Avionics PCBs

In the demanding world of military avionics, where every gram and millimeter counts, the need for reliable, lightweight, and flexible solutions is paramount. Lightweight Flat Flexible Cables (FFCs) have emerged as a game-changer for Printed Circuit Boards (PCBs) in military applications. These cables offer a unique combination of durability, flexibility, and weight savings, making them ideal for the harsh environments and tight spaces typical of avionics systems. As military technology advances, the demand for more efficient and compact wiring solutions grows, and FFCs are stepping up to meet these challenges.

The use of FFCs in military avionics is not just about reducing weight; it’s about enhancing performance, reliability, and maintainability. Traditional wiring harnesses are bulky and rigid, often complicating installation and maintenance. In contrast, FFCs provide a sleek, streamlined alternative that can withstand extreme temperatures, vibrations, and electromagnetic interference. This article delves into the various aspects of FFCs, exploring their benefits, materials, design considerations, and applications in military avionics.

Benefits of Lightweight Flat Flexible Cables

One of the most significant advantages of FFCs is their weight reduction compared to conventional wiring. In military aircraft, every ounce saved translates to improved fuel efficiency and payload capacity. FFCs are incredibly thin and lightweight, yet they maintain high conductivity and durability. This makes them perfect for avionics systems where space and weight are at a premium.

Another key benefit is their flexibility. Unlike rigid cables, FFCs can bend and twist without compromising performance. This flexibility allows for easier routing around tight corners and through confined spaces, reducing the risk of damage during installation or operation. Additionally, FFCs are less prone to wear and tear, ensuring longer service life and lower maintenance costs.

Materials and Construction

The materials used in FFCs are carefully selected to meet the rigorous demands of military avionics. Typically, these cables consist of thin layers of conductive material, such as copper, sandwiched between insulating layers of polyimide or polyester. These materials offer excellent thermal stability, chemical resistance, and mechanical strength, ensuring reliable performance in extreme conditions.

The construction of FFCs also plays a crucial role in their performance. The conductive traces are often arranged in a flat, ribbon-like configuration, which minimizes signal interference and crosstalk. This design is particularly important in avionics, where signal integrity is critical for communication and navigation systems. Advanced manufacturing techniques, such as precision etching and laser cutting, ensure that FFCs meet the exacting standards required for military applications.

Design Considerations

When designing FFCs for military avionics, several factors must be taken into account. First and foremost is the environmental conditions the cables will face. Military aircraft operate in a wide range of temperatures, from sub-zero altitudes to scorching desert environments. FFCs must be designed to withstand these extremes without degrading in performance.

Another critical consideration is electromagnetic interference (EMI). Avionics systems are highly sensitive to EMI, which can disrupt signals and cause malfunctions. FFCs are often shielded with conductive layers or coatings to minimize EMI and ensure reliable operation. Additionally, the cables must be designed to resist vibrations and mechanical stress, which are common in military aircraft.

Applications in Military Avionics

FFCs are used in a variety of military avionics applications, from cockpit displays to radar systems. Their lightweight and flexible nature makes them ideal for use in tight spaces, such as behind instrument panels or within wing assemblies. They are also commonly used in communication systems, where signal integrity is paramount.

One notable application is in unmanned aerial vehicles (UAVs), where weight and space constraints are even more critical. FFCs enable the compact and efficient wiring needed for these advanced systems, ensuring reliable performance in the field. As military technology continues to evolve, the role of FFCs in avionics is expected to grow, driving further innovations in their design and functionality.

In conclusion, Lightweight Flat Flexible Cables are revolutionizing military avionics by offering a perfect blend of weight savings, flexibility, and reliability. Their advanced materials and construction make them well-suited for the harsh conditions of military operations, while their design versatility ensures they can meet the evolving needs of modern avionics systems. As the demand for more efficient and compact wiring solutions increases, FFCs will undoubtedly play a pivotal role in shaping the future of military technology.

2025-08-09szshuoqiang -

Discover The World Of LED Technology Innovative Designs And Energy Saving Benefits

Welcome to the fascinating realm of LED technology, where innovation meets sustainability. This article delves into the dynamic world of LEDs, exploring their cutting-edge designs and remarkable energy-saving advantages. As global awareness of environmental issues grows, LEDs have emerged as a pivotal solution, transforming how we light our homes, offices, and cities. Join us on this journey to uncover how these tiny yet powerful devices are reshaping the future with efficiency and style.

Innovative Designs in LED Technology

LED technology has revolutionized lighting design, offering unparalleled flexibility and creativity. From sleek, minimalist fixtures to customizable color-changing systems, LEDs enable designers to craft solutions that blend seamlessly with modern aesthetics. Their compact size allows for integration into various applications, such as architectural lighting, automotive displays, and even wearable tech, pushing the boundaries of what's possible.

Moreover, advancements like smart LEDs, which can be controlled via smartphones or voice assistants, add a layer of convenience and personalization. These designs not only enhance visual appeal but also improve functionality, making LEDs a cornerstone of contemporary innovation in multiple industries.

Energy-Saving Benefits of LEDs

One of the most significant advantages of LED technology is its exceptional energy efficiency. LEDs consume up to 80% less energy than traditional incandescent bulbs, translating to substantial reductions in electricity bills and carbon footprints. This efficiency stems from their ability to convert a higher percentage of energy into light rather than heat, making them both eco-friendly and cost-effective.

Additionally, LEDs have a much longer lifespan, often lasting over 25,000 hours, which reduces the frequency of replacements and waste. This durability, combined with lower energy usage, positions LEDs as a key player in global efforts to promote sustainability and combat climate change through smarter resource management.

Environmental and Economic Impact

Beyond individual savings, the widespread adoption of LED technology contributes to broader environmental benefits. By decreasing energy demand, LEDs help reduce greenhouse gas emissions from power plants, supporting cleaner air and a healthier planet. Their mercury-free composition also makes disposal safer compared to other lighting options, minimizing toxic waste.

Economically, the LED industry drives job creation and innovation, fostering growth in sectors like manufacturing, technology, and green energy. As governments and organizations worldwide incentivize energy-efficient solutions, LEDs are becoming integral to sustainable development strategies, offering a win-win for both the economy and the environment.

2025-09-15tuiguang2 -

Imagine embarking on a month-long journey abroad, where your itinerary seamlessly blends high-stakes business meetings, elegant evening galas, and serene days on sun-drenched beaches. The very thought of packing for such a diverse adventure can be daunting, often leading to overpacking chaos or the frustration of leaving behind essential items. Yet, the promise encapsulated in the phrase \"Packed to perfection, this expansive suitcase holds everything needed for a month abroad, from formal attire to beachwear, neatly organized in separate compartments\" offers a compelling solution. This isn\'t merely about a piece of luggage; it\'s a statement about mastering the art of travel. It speaks to the modern traveler\'s desire for efficiency, style, and peace of mind, transforming the pre-travel anxiety into a curated, confident preparation. The concept challenges the conventional packing woes by proposing a single, intelligently designed vessel capable of accommodating the multifaceted demands of extended travel. As we delve into this idea, we explore not just a suitcase, but a philosophy of organization and foresight that can redefine the travel experience.

The Philosophy of \"Packed to Perfection\": Beyond Mere Luggage

The notion of packing to perfection transcends the simple act of filling a bag. It represents a meticulous, thoughtful approach to preparation that considers the entirety of the travel experience. It is the antithesis of last-minute cramming, instead advocating for a strategic selection process where every item has a purpose and a place. This philosophy is rooted in the principles of intentionality and efficiency, aiming to reduce decision fatigue while on the road and to ensure readiness for any occasion.

Furthermore, this approach acknowledges the psychological burden of clutter and disorganization. A perfectly packed suitcase becomes a portable sanctuary of order, providing a sense of control and calm from the moment one leaves home. It allows the traveler to focus on the experiences ahead rather than worrying about wrinkled clothes or misplaced belongings. In essence, \"packed to perfection\" is the first step in cultivating a mindful and enjoyable journey, where the luggage serves as a reliable, silent partner in adventure.

Architectural Design: The Expansive and Intelligent Shell

At the heart of this promise is the suitcase itself—expansive yet manageable. Modern luggage engineering utilizes lightweight, durable materials like polycarbonate or aerospace-grade aluminum to create a shell that is both protective and surprisingly capacious. The \"expansive\" nature isn\'t just about raw volume; it\'s about smart geometry. Innovative designs often feature recessed wheels and telescopic handles to maximize internal space, while maintaining a silhouette compliant with airline carry-on or checked baggage regulations.

This intelligent design extends to the structure. A rigid frame protects delicate items, while strategic flexibility allows for that final compression. The expansion zipper, a key feature, offers a calculated increase in capacity for the return journey, accommodating souvenirs without the need for a second bag. The exterior is often equipped with integrated TSA-approved locks, scratch-resistant surfaces, and 360-degree spinner wheels that glide effortlessly through crowded airports. This combination of robustness and thoughtful detail forms the foundational canvas upon which the perfect pack is built.

The Compartment Revolution: A Place for Everything

The true genius of the perfect pack lies in its interior organization system. The phrase \"neatly organized in separate compartments\" is the cornerstone of its functionality. Gone are the days of a single, gaping cavity. Instead, the interior is a meticulously zoned ecosystem. A common design features two main sides: one with a sturdy cross-strap system for securing bulkier items, and the other a web of adjustable straps and zippered panels.

These separate compartments are transformative. One might be a padded, fleece-lined pocket specifically designed for laptops or tablets. Another could be a waterproof pouch for toiletries or damp swimwear. Garment folders or built-in suit carriers keep formal attire crisp, while compression straps or zippered bags minimize the volume of softer items like knitwear. Shoe compartments, often with anti-odor lining, isolate footwear from clothing. This compartmentalization does more than organize; it categorizes your trip, allowing for rapid access and inventory checks without disrupting the entire contents. It turns packing and unpacking from a chore into a logical, almost satisfying, process.

The Month-Long Capsule Wardrobe: From Formal to Beachwear

Accommodating a month\'s worth of varied attire is the ultimate test. The solution lies not in packing 30 entirely different outfits, but in curating a versatile, mix-and-match capsule wardrobe. The suitcase\'s organization supports this strategy perfectly. Formal attire—a tailored blazer, dress pants, a little black dress, and elegant shirts—can be placed in the garment section, perhaps with a few wrinkle-release sprays.

For casual and beachwear, the strategy shifts to lightweight, quick-drying fabrics. A few pairs of versatile shorts, neutral-colored t-shirts, a sun hat, and a couple of swimsuits form the core. The key is layering: a sarong doubles as a beach cover-up, a scarf, or a light blanket. A smart-casual outfit can often be deconstructed; the trousers from a formal set paired with a polo shirt create a perfect dinner-by-the-sea look. The separate compartments allow these categories to coexist without cross-contamination, ensuring that a sandy beach towel never brushes against a silk blouse. This thoughtful curation, enabled by the suitcase\'s design, proves that style and practicality are not mutually exclusive on the road.

Packing Methodology: The Art of Spatial Optimization

Even with the best suitcase, perfection requires technique. The methodology involves more than folding. For non-compartmentalized sections, the bundle wrapping technique—where clothes are rolled around a central core—minimizes wrinkles and maximizes space. For the compartmentalized zones, the principle is one of categorization and sequence. Heavier items like shoes and toiletry kits are packed first, positioned near the wheeled base for better balance.

Then, utilizing every dedicated pocket becomes crucial. Socks and belts are tucked into shoes. Electronics cables are coiled into small pouches. Jewelry is threaded through buttonholes or stored in a dedicated roll. The final step is a strategic use of compression. Whether through built-in compression straps or separate packing cubes, this step locks everything in place, creating a dense, stable block of belongings that prevents shifting during transit. This meticulous methodology, supported by the suitcase\'s architecture, is what transforms a collection of items into a cohesive, travel-ready unit.

The Psychological and Practical Payoff

The benefits of achieving this packed perfection are profound and multifaceted. Practically, it streamlines every travel transition. Navigating airport security is faster with organized electronics and liquids. Checking into a hotel involves simply placing the suitcase on a rack and opening the relevant compartment, rather than a full unpack. Lost items become a rarity, as everything has a designated home.

Psychologically, the payoff is even greater. It eliminates the pre-trip stress of \"what if I forget something?\" and the in-trip frustration of rummaging. It grants a sense of preparedness and competence that enhances the traveler\'s confidence. The mental space freed from worrying about belongings is instead filled with anticipation for new experiences. The perfectly packed suitcase, therefore, becomes more than a container; it is an enabler of seamless, joyful, and immersive travel, proving that the journey truly begins with how you pack.

2025-12-08dgdiwoli -

In the fast-paced world of modern beauty and on-the-go lifestyles, keeping your essential cosmetics organized and secure can often feel like a daunting challenge. Whether you\'re rushing to a morning meeting, embarking on a weekend getaway, or simply navigating your daily routine, the last thing you need is a disorganized bag with products spilling and getting damaged. This is where the concept of a dedicated, thoughtfully designed makeup bag becomes not just an accessory, but a necessity. Imagine a solution that combines robust protection with intelligent organization—introducing the water-resistant mini makeup bag with multiple compartments. This innovative product promises to transform how you store and transport your beauty essentials, offering unparalleled convenience by ensuring everything has its place and remains shielded from the elements. It’s more than just a pouch; it’s a personal organizer crafted for the discerning individual who values both style and practicality, merging durability with sleek design to keep your products impeccably tidy and protected no matter where life takes you.

Unmatched Protection: The Water-Resistant Advantage

At the core of this mini makeup bag\'s design is its exceptional water-resistant capability, a feature that sets it apart from ordinary cosmetic carriers. Constructed from high-quality, durable materials, the bag acts as a reliable shield against accidental spills, humidity, and light rain. This is particularly crucial for preserving the integrity of your makeup products, many of which can be sensitive to moisture. Powders can become cakey, creams may separate, and delicate tools like brushes can harbor mold if exposed to damp conditions. With this bag, such worries become a thing of the past.

Furthermore, the water-resistant property extends the lifespan of both the bag and its contents. Whether you\'re traveling through unpredictable weather or storing the bag in a humid bathroom, the interior remains dry and secure. This resilience ensures that your investments in high-end cosmetics are safeguarded, allowing you to enjoy your favorite products without fear of damage. The peace of mind that comes with knowing your belongings are protected is an invaluable aspect of the convenience this bag offers, making it an indispensable companion for daily use and adventures alike.

Intelligent Organization: Multiple Compartments for Every Need

Beyond protection, the bag excels in organization through its cleverly designed multiple compartments. Instead of a single cavernous space where items disappear into a jumbled mess, this bag features dedicated sections tailored for different product types. For instance, separate pockets can hold brushes upright to maintain their shape, elastic loops secure lipsticks and liners in place, and zippered mesh pockets keep smaller items like earrings or bobby pins from getting lost. This systematic layout transforms the frustrating search for a specific product into a quick and effortless retrieval.

The benefits of such organization extend to efficiency and hygiene. By assigning each product its own spot, you minimize the risk of contamination—no more foundation smudges on your blush or broken eyeshadow palettes from loose items knocking together. Additionally, the compartments encourage a minimalist approach, helping you prioritize only the essentials and avoid overpacking. This not only keeps the bag lightweight and portable but also streamlines your routine, saving precious time during busy mornings or last-minute touch-ups. Ultimately, the multiple compartments turn chaos into order, embodying the very essence of convenience.

Compact and Portable Design: Convenience on the Go

Despite its robust organizational features, the bag maintains a mini, compact form factor that prioritizes portability. Its sleek dimensions allow it to fit effortlessly into larger handbags, backpacks, or even be carried independently, making it ideal for travel, gym visits, or daily commutes. The lightweight construction ensures it doesn\'t add unnecessary bulk, while sturdy zippers and reinforced seams guarantee durability even with frequent use. This balance of size and strength means you never have to compromise between carrying your essentials and maintaining a clutter-free lifestyle.

Moreover, the bag\'s portability enhances its versatility. It can seamlessly transition from a makeup organizer to a holder for other small items like medications, tech accessories, or art supplies, adapting to various needs beyond beauty. The compact design also encourages mindful packing, prompting you to select only what you truly need and reducing the temptation to carry excess baggage. Whether you\'re hopping on a plane or simply moving from room to room, this mini makeup bag ensures your belongings are always within reach, organized, and ready for use.

Aesthetic Appeal and Durability: Style Meets Function

While functionality is paramount, this water-resistant mini makeup bag does not sacrifice style. Available in a range of colors and finishes, from classic neutrals to vibrant hues, it complements personal tastes and adds a touch of elegance to any setting. The materials are not only practical but also aesthetically pleasing, with easy-to-clean surfaces that resist stains and maintain their appearance over time. This attention to detail means the bag remains a stylish accessory that you can proudly display, whether on your vanity or during travels.

Durability further enhances its appeal, as the bag is built to withstand the rigors of daily life. Reinforced stitching, quality zippers, and resilient fabrics ensure it holds up against wear and tear, offering long-term value. Unlike flimsy alternatives that quickly show signs of aging, this bag is an investment in both form and function. By merging sleek design with rugged construction, it proves that practicality and beauty can coexist, providing a reliable solution that you\'ll appreciate for years to come.

Enhancing Daily Routines: A Tool for Simplified Living

Ultimately, this makeup bag transcends its role as a mere container to become a tool that enhances overall daily efficiency. By keeping products tidy and protected, it reduces stress and saves time—two precious commodities in today\'s busy world. Imagine starting your day without rummaging through a messy bag or dealing with damaged items; instead, you experience a smooth, organized routine that sets a positive tone for the hours ahead. This sense of order can extend beyond makeup, influencing how you manage other aspects of your life by promoting habits of organization and care.

Additionally, the bag fosters a sense of preparedness, allowing you to face unexpected situations with confidence. Whether it\'s a sudden meeting, a spontaneous trip, or a quick touch-up before an event, having your essentials neatly arranged ensures you\'re always ready. It embodies the modern desire for products that simplify complexity, offering a tangible solution to everyday challenges. In embracing this water-resistant mini makeup bag, you\'re not just acquiring an accessory; you\'re investing in a lifestyle of convenience, where every detail is considered to support your dynamic, on-the-go existence.

2025-12-12dgdiwoli

Latest Blogs

Unmatched Quality: Premium-Grade Materials and Structural Strength

The key to this outstanding travel bag is the stringent quality standard for selecting the materials used to construct the bag. Only the highest quality components are selected, which not only convey a sense of quality but also enable the bag to hold up under the most demanding conditions found in today\'s modern travel environment. As an example, the exterior shell of the bag may be made from full-grain leather, an extremely durable material with the capacity to age into a one-of-a-kind finish and texture. Alternatively, the exterior shell may be constructed from state-of-the-art, high-performance fabrics such as ballistic nylon, which offers users unparalleled protection against tears, abrasions, and moisture. The materials used for constructing these bags have been specifically selected based on the proven reliability, high-performance and long-term durability of the given material.

While every component of these travel bags represents a commitment to durability.Consider planning a vacation that has been premeditated to the fullest extent possible. Whereby items that you will take with you have been packed precisely as opposed to haphazardly plopping them into a suitcase, plus how those bags made a statement about your superior taste and flair.

These exclusive travel bags are created for customers who want to elevate their travel experience beyond just a practical item. In an age of mass-produced, \"fast fashion\" products, the line of travel bags that these companies produce has a long manufacturing life or is created from high-quality materials with thoughtful organizational systems and quality craftsmanship that sets them apart from most commercial luggage available today.

These travel bags are much more than a form of luggage; they are your trusted travel companion. You will have the confidence to navigate the busiest airports, confidently conduct business meetings, and explore unfamiliar destinations.

The collection of travel bags and their corresponding slogan \"Travel in Confidence\" are representative statements of the confidence that you receive as a traveler while investing in an exceptional piece of luggage built to last, evolve, and enhance each travel experience.

Unmatched Quality: Premium Grade Materials and Structure

The primary reason for the exceptional quality of this travel bag is the extremely high-quality standard, which determines the materials used to create the bag. The materials selected represent only the best of the best in quality and will allow this bag to withstand the stresses of modern travel.

For instance, the travel bag\'s exterior shell can be made of full-grain leather which has excellent properties of durability but will develop its own unique finish and texture over time. The material of a bag can also be made from high-performance technical fabrics such as ballistic nylon which is manufactured specifically for the protection against tearing, abrasion, and moisture. The quality of the materials used for all travel bags produced in this collection are chosen based on proven reliability and exceptional-performance longevity of the material itself.The stress points of a travel bag are sewn with reinforced stitches, usually done by stitching together two pieces of fabric by hand or using precision machinery, so the seams do not come apart from pressure on them. The zippers on these bags come from reputable manufacturers to guarantee that they do not get stuck, even when people place a lot of weight in the bag. The metal clasps and footings of the bags are made of metals that resist corrosion, a reflection of the manufacturer\'s attention to detail. All of this means that the bag will age gracefully, developing its own personality, and not break down over time. A customer is investing in a travel bag that will protect their belongings and maintain its form and function from trip to trip. In addition to that, it represents the most sustainable option in terms of long-lasting quality.

Intelligent Design: Organization Systems For Seamless Travel

When people look at ordinary bags, they see several compartments within the bag. An intelligent organization system has been incorporated into a travel bag to make your life easier as you travel. The interior of the bag has been designed with a defined architecture that includes separate spaces for laptops, tablets, files, and accessory items. The padded sleeves in the bag are used to protect your electronic devices from being damaged, and the multiple compartments have been designed to sort your belongings, including chargers, pens, passports, and tickets. The frustration that accompanies the \"black hole\" effect, courtesy of a large main compartment, will be eliminated from your travel experience.

Smart Design Features For Flexible Use

The smart features of these bags extend to their ability to conform to different sizes and shapes. There may be modular inserts or compression straps available, which will allow you to change the amount of space available depending on whether you\'re packing for a weekend trip or an extended trip of two weeks or more.

Use of exterior access points allows access to your laptop or water bottle without opening the main compartment, making access easier both during security checks as well as when you are travelling. Some travel bag designs also feature organisational systems for charging cables or hidden pouches for valuable items, creating an all-encompassing message about how to properly pack and prepare for the journey and maintain a stress-free experience.

Timeless Elegance: Aesthetic Appeal Beyond Trends

With ever-changing fashions dominating our society today, the Travel Bag represents an expression of timeless elegance that goes beyond season. The design philosophy applies clean lines, symmetry of proportions and limited colour palates (black, brown deep navy and deep olive); all of which create an overall effect of beauty achieved through blending form and function harmoniously. The bag\'s eye-catching silhouette lends itself to multiple uses; it is appropriate for the corporate office, the lobby foyer of a luxury hotel, or your preferred coffee shop in a quaint tourist/community area.

This style was created to draw attention to the individual\'s personal style rather than create an overwhelming presence or distraction. The elegance of this bag originates from its material\'s texture, manufacturing process, and quality hardware. Those who own a Travel Bag project an image to others of sophistication or discerning character without ever needing to verbalise it. As it is not designed to keep pace with contemporary trends, year after year this bag maintains its stylish stature. Owning one demonstrates appreciation for timeless design and supports the notion of travel being a multi-dimensional occurrence (for example, across the first mile to the thousandth).

Confidence Factors: How Superior Craftsmanship Improves The Travel Experience

The amalgamation of premium material selection, intelligent organisation practices and timeless design principles instil within travellers a heightened sense of confidence. By virtue of the Travel Bag\'s inherent ability to secure, safely store and quickly access personal items, there is no need to worry about a broken zipper accidently spilling all of your belongings onto an airport terminal floor, or a frayed strap failing at an inopportune time. The reliability of the Travel Bag extends the ability of a traveller to navigate through life confidently.

The versatility and appropriateness of the Travel Bag are further indicators of how they instil confidence in their owners\' ability to adapt in various work environments. The Travel Bag can function as a mobile office for digital nomads needing to set up shop wherever they land; give professionals the tools necessary to present themselves effectively at an international conference, or simply provide leisure travellers with comfort and style. As such, the Travel Bag eliminates a number of friction points associated with travelling, allowing the traveller to seamlessly transition from one travel experience to the next. Additionally, the pride of owning a beautifully crafted item instills in the owner a heightened sense of confidence. Rather than simply carrying a bag, you possess an accessory that reflects both your standards and your aspirations, making every journey from across the globe to your everyday commute a confident and graceful experience.Having access to exterior access points allows you to access your laptop or water bottle without having to open your travel bag\'s main compartment. This makes it easier for you to access your laptop and water bottle at security checkpoints and while traveling by providing you with additional options during your travels. Many travel bag designs also include a series of compartments within the bag to allow for organisation of charging cables or to allow for additional storage of small valuable items, providing a complete overview of how to prepare, pack and travel comfortably and stress-free.

The Travel Bag is a representation of unparalleled quality and sophistication that defines an individual as a person of style. Even with the constant changes in fashion elements, the Travel Bag will remain a consistent expression of class, elegance and sophistication to anyone who uses it. Clean lines, balanced proportions and a limited colour range of black, brown, deep navy and deep olive provide the overall effect of beauty achieved by combining form and function. The signature design of the Travel Bag is an elegant silhouette that will serve in multiple environments; it is equally suitable for the office, at the front desk of a five-star hotel or your favourite coffee shop in a charming tourist/community area.

The Travel Bag design draws on the personal style of the owner without imposing an overwhelming presence. The materials, manufacturing techniques and high-quality hardware with which the Travel Bag is constructed contributes to the elegance of the Travel Bag and communicates to others that the owner is sophisticated and discerning, without having to say so. As the Travel Bag is not made to be trend-oriented, it continues to maintain its status as a stylish piece of luggage year after year. By owning a Travel Bag, the owner demonstrates an appreciation for timeless design and encourages the concept of travelling as having a multi-dimensional experience (i.e., the first mile of travel to the one thousandth).

The combination of premium material choices, intelligent organisation systems, and timeless design principles give travellers a higher level of confidence. The ability to securely store, easily accessible and safely transport personal belongings gives travellers peace of mind when travelling. While there is no fear of an accidental broken zipper spilling all your belongings onto the terminal floor or a frayed strap at the most inopportune time, the Travel Bag\'s dependability permits travellers to confidently navigate through life.

Versatility and appropriateness is another source of confidence in Travel Bag owners\' ability to adapt to various work situations. The Travel Bag will serve as the mobile office of digital nomads, enabling them to set up wherever they land; allow professionals the ability to present themselves effectively at an international conference; or provide leisure travellers with comfort and style. Thus, the Travel Bag reduces a number of friction points related to travelling, while enabling the traveller to transition smoothly from one experience to the next. The pride that comes from owning a well-made piece of luggage results in heightened confidence for the owner. Essentially, you possess an accessory that expresses both who you are and what you hope to accomplish, enabling you to approach every trip, whether across the globe or your daily commute, with confidence and grace.

Road Warrior is constructed of premium materials that meet the highest quality standards. All Road Warrior bags are constructed from high-quality materials that have been selected for their exceptional properties, including strength and durability, to withstand the rigors of daily use and keep Road Warrior looking brand new long after it leaves the showroom. Road Warrior\'s exterior is made from either high-density, water-resistant nylon and/or full-grain leather. All Road Warrior materials were selected for their tactile character and ability to develop a rich patina with time, representing how and where you traveled.

All Road Warrior bags are assembled with the utmost attention to detail; every stitch and seam in every Road Warrior bag demonstrates the care of the artisan who handled it.Its construction has reinforced stress points, precision stitched handles, and strong, smooth gliding zippers. Custom anodized aluminum or brushed metal hardware includes zipper pulls and clasps, both of which are designed to resist corrosion and add a level of aesthetics. This level of quality builds a bag that will last many years as a reliable companion for everything from daily commutes to cross-continent travel, and not just an accessory that can be tossed away.

Due to the innovative organization concept, this bag is revolutionary. It has much more than just compartments, providing an intelligent modular storage system designed with real-world functionality. The padded laptop sleeve accommodates laptops up to 16 inches, while a separate tablet pocket and secure document holder keep your important documents and technology organized and readily accessible. To help you pack everything from a suit to casual weekend clothing without wrinkling, the main compartment features adjustable dividers and compression straps.

Also developed were strategically located accessory pockets inside and outside the bag. Quick access pockets are located on the sides and front of the bag for easy access to tickets, passports, and phones. The interior of the bag contains organizational panels designed for items such as pens, charging cables, power banks, and water bottles. Hidden locks, which are secure locations for valuables, offer the highest level of protection. The intelligent design of the Bag minimizes potential for \"Black Hole\" or overwhelming chaos which often occurs when packing multiple items in one bag. When utilizing this design, each item has an identifiable location, which not only assists with packing/unpacking but also offers you more of an opportunity to experience the destination while travelling.

While there is much appeal to a bag with a Modern-Day-business look, the Layout itself also provides for ease of use which helps you easily transition between Business/Personal needs. The clean lines, lack of visible Branding and modern colour options (Charcoal Grey, Deep Navy Blue & Classic Black) enable this bag to fit in any setting from the Corporate Business Workplace through to a Trendy Café or Boutique Hotel Lobby.

The Bag has a Sleek Modern Design which is Ergonomically designed to provide maximum capacity yet limit bulkiness. The Bag\'s body maintains a streamlined silhouette as to appear professional while still allowing you to present an organized image.

The Bag\'s many configurations, including different carrying options, allow you both practicality and style while On-The-Go. A padded, removable shoulder strap provides you with Hands-Free Carrying Capability when travelling; while an additional option, the dual handle support feature provides you with a look that is suitable for Formal Business Intermediate Events. Some Models even incorporate an integrated Trolley Sleeve that supports connection to a Rolling Luggage Handle, thereby offering a single intelligent system to facilitate Left/Right Off Boarding of other luggage when travelling.Ergonomic Engineering: Comfort for Extended Use

Realizing that most travelers end up having to carry all their belongings for long periods, this travel partner has been designed from the ground up with ergonomics in mind. The back panel of the bag is padded and typically has a breathable mesh or channeled foam for maximized air circulation, thus minimizing entropy from perspiration and fatigue. The weight distribution of the bag is also engineered to ensure proper positioning on the body, and the bag\'s structural design and strap placement will all be considered to keep the bag riding close to the body to avoid putting any strain on the shoulders and back during a heavily-loaded state.

In terms of user-friendliness, all functional components of the bag are designed for smooth operation. The folds of the zipper glide easily; magnetic clasps open and close with one hand; and all handles are padded for ease of use and comfort. The entire design process was completed while keeping the complete travel-cycle of a bag in mind. For instance, traveling via air, then carrying the bag while on a lengthy trek within an unfamiliar metropolitan area. Focusing intently on user comfort supports the journey to shift the act of carrying from an obligatory length of time to one of ease within the travel experience; thus allowing you to reach your destination much more relaxed and organized than when you began your voyage.

Sustainable Product: Conscious Manufacturing

With the current surge in eco-consciousness, this travel partner has also carved a niche for demonstrating its active participation in protecting the planet. Our premium products are nearly exclusively made from eco-sourced materials, including recycled upholstery fabrics as well as leather produced by environmentally-conscious tanning operations. Additionally, the lifetime of use that each product provides contributes directly to reducing the effects of the \"throw away\" culture that has fueled the rise of fast fashion and planned obsolescence.

The manufacturing processes of the bags are designed to reduce waste and provide ethical working conditions for employees engaged in producing our products. Therefore, choosing to purchase any of our bags indicates both your commitment to superior quality and style, as well as your endorsement of a better future for our planet. It is a travel partner that will meet the needs of today\'s conscientious traveler who wishes to travel the world while having no negative environmental impact. The additional integrity associated with the product significantly enhances the value/importance of the product as a statement of both personal and global ownership.

Using the wrong bag can make traveling stressful due to damaged items, frayed nerves, or physical stress associated with carrying the bag. This makes it imperative to meet all of these challenges with one bag. This bag has been developed with the needs of frequent travelers in mind. This bag is constructed of extremely durable materials and water-resistant material, has reinforced zippers, and has ergonomic features designed to create an enjoyable travel experience. It is not just an accessory; this item has been developed through extensive research to provide users with a reliable product that will withstand the rigours of travel while providing comfort and peace of mind.

Whether travelling through the hectic terminals of an international airport or facing the unexpected weather conditions of a large urban area, this travel bag is built to be a strong, reliable, and durable companion to those who travel the world. This bag combines strong protection with intelligent design to address the unique challenges of an ever-evolving world.

Unmatched Durability and Protective Design Elements

The foundation of this bag\'s construction is durability. For any product subject to the strains and stresses of continual use while travelling, durability is a non-negotiable aspect. In conjunction with durability is the first line of defence of this bag: The material used to construct the exterior of the bag is an advanced water-resistant material. This is not simply a layer applied on top; this is a high-performance material technology that will shield the contents of the bag from damage caused by rain from a sudden downpour, spilled drinks, and moisture from the storage area of a plane.This tightly woven, treated fabric protects against any contents being damaged or moistened in varying climates or unexpected weather events, providing an additional layer of protection simply due to being proactive. Anything placed inside can remain dry and safe while there isn\'t a major form of anxiety when traveling with things like important documents, electronics, clothing, etc.

In addition to being water-resistant, the material has also been selected for its high denier and abrasion-resistance; therefore, it can withstand being scratched and torn as well as being stowed underneath the seat of an airplane, placed on rough surfaces, or handled multiple times by various means of transportation (the material\'s durability will ensure the bag\'s structural integrity has been maintained over time). Therefore, it is an investment in the bag over time, rather than a cheap product that will ultimately be disposed of. This durability is synonymous with the reliability of the traveler, as they can concentrate on their itinerary instead of worrying about how their bag will fare.

Fortified Security: Reinforced Zippers and Structural Integrity

Not only does the bag provide superior protection from moisture and other elements through the use of the material, but the critical point of access (the zippers) and closure is also fortified. The zippers used on this product are significantly upgraded over the typical zippers seen on bags already produced. For instance, they are typically larger zippers with metal materials (corrosion-resistant aluminum) and hardened plastic polymers; they are made with a self-repair feature designed to prevent the splitting of the zipper under stress.

Because of the width of the zippers and the number of stitches used, the majority of the time the stitching is reinforced (at least double-stitched, if not triple-stitched) around the zipper track so that as much force can be applied to the zipper track while using the bag without damaging the zipper track or the interior of the bag.

The focus on fortified closures provides a dual purpose: to provide security and longevity.

To protect your belongings from theft or accidental openings, a reliable zipper will provide a level of confidence when using your bag in crowded environments. Reinforced zippers are much less reliable than a regular zipper that have tendencies to jam or break during use. If you\'re using less-than-reliable zipper hardware, it can render your bag unusable in the middle of your travels. By investing in this level of hardware, you guarantee a level of smooth and dependable operation.

Additionally, some models have lockable zipper pulls to add another layer of security when you\'re travelling with the bag, or when you\'re temporarily leaving it in a hotel room.

Ergonomically Designed to Allow for Easier Mobility

Given that many frequent travellers carry bags for extended periods of time, an ergonomically designed travel bag reduces the potential for physical stress related to travelling with the bag. This has been accomplished through a multi-faceted approach. It uses breathable, moisture-wicking foam that has been extensively padded through both the back panel and shoulder straps. The foam will conform to and contour to your body, so that the weight of the bag is distributed across your shoulders and back rather than being concentrated on a small pressure point(s). Additionally, since the material is breathable, there is no accumulation of heat and sweat, further improving comfort while walking long distances in an airport terminal or city streets.

The ergonomic considerations of this bag design are comprehensive. A contoured rigid back panel provides lumbar support and structural support, ensuring that the contents of the bag will not cause discomfort against your back during use.Reliable zippers are a dependable source of security and confidence when navigating busy places and protecting valuables against theft or inadvertent openings. When compared to Standard Zippers, Reinforced Zippers are less reliable because they have a higher tendency to break or jam during operation. Therefore, if you utilize zippers that lack reliability, you will find yourself having to discard orA quality zipper protects your possessions from being stolen and keeps them securely inside the bag. You can trust a strong zipper when traveling and using your bag in busy places. Zippers reinforced with extra stitching and materials provide much less assurance than a good-quality zipper that tends to become jammed or fail while in use. If the zipper hardware fails, it will not allow you to use your bag effectively while you are traveling. With this investment in hardware, you have an assurance of a reliable and smooth operation.

Many of these types of bags come with lockable zipper pulls to add extra security when traveling with the bag or leaving it at a hotel for short periods.

Ergonomically Designed For Easier Mobility

Frequent travelers often carry their travel bags for long durations. In order to reduce the likelihood of physical stress, a properly designed ergonomic travel bag reduces the effects of carrying a heavy bag. The ergonomic design of the bag provides a multi-pronged solution to this problem. It features breathable, moisture-wicking foam padding throughout both the back panel and shoulder straps. The padding is designed to conform to the shape of your body, distributing the weight of the bag over your entire back and shoulder area and eliminating concentrated pressure points. Additionally, since the padding is made of breathable materials, the bag will continue to breathe while being carried for long distances in airports or busy city streets, keeping your sweat away from your body.

In addition to the overall ergonomic design considerations, the bag features a contoured, rigid back panel that provides full lumbar and support for the bag\'s contents, thereby preventing discomfort against your back while using the bag.A well-designed zipper provides you the confidence to use a bag safely in a crowded place as it will keep your belongings safe from theft and accidental opening. Regular zippers are much more dependable than reinforced zippers, which tend to jam or break while in use. If your zipper is unreliable, it can leave you with a broken bag during your travels. For that reason, making an investment in a heavy-duty zipper gives you a guarantee of reliable performance.

Some bags come equipped with lockable zipper pulls for added security while travelling and while temporarily leaving your bag in a hotel room.

The design of this bag is ergonomically constructed to allow ease of movement for those that carry a bag while travelling for extended periods of time. This design is achieved through a multi-faceted approach to reduce the physical strain caused by travelling with a bag. It utilizes breathable foam that is moisture-wicking, and is heavily padded in the back panel and shoulder straps. The foam conforms and contours to your body, allowing for even distribution of the weight of your bag across your shoulders and back, rather than concentrating the load on a single pressure point. It also has breathable material so you do not get hot and sweaty while walking long distances, either in an airport terminal or the streets of a city.

The ergonomic design of this bag is extensive. The rigid contoured back panel has lumbar and structural support, so the contents of the bag will not cause discomfort against your back while you are using it.Commonly adjustable, such straps may also have a sternum strap or hip belt for heavier loads, transferring weight onto stronger core and hip muscles, thereby improving balance and reducing fatigue. A thoughtfully designed handle, frequently incorporating a soft-grip padded section, provides comfort when carrying the bag by hand. Each area of contact between the user and the bag is engineered to lessenAn adjustable strap system, a sternum strap for load bearing or a hip belt is included with many heavy-duty backpacks so that the pressure from the back of the user is distributed evenly to his/her stronger core and hip muscles for better balance and less chance of fatigue while walking. The handle is also designed with a soft, padded grip section so that it is comfortable for the user to carry the bag by hand. The best-performance points at which the user interacts with his/her bag create a sense of weightlessness, making travelling more enjoyable and easier.

As important as protection against internal damage is to the user, organisation is also very important for preventing damage caused by items being jostled against each other while travelling. The interior of this bag is like a work of art in the way it is organised intelligently using compartments, with the largest compartment having dividers, other compartments having varying sizes of zippered pockets, and also having separate sleeves that hold a laptop, a tablet and a folder. All of the partitions within the bag serve to cushion the user\'s electronics from any impact during travel. The User Organisation System within the bag allows the user to separate their clean clothing from their shoes, cables from toiletries, wet items from dry items, and maintain organisation and quick access throughout their travels.

The same logical layout employed internally within the bag is applied to the external features of the bag that allow the user to easily retrieve important items. Quick access pockets located at the front or the sides of the bag permit access to passports, boarding passes or mobile phones without having to open the primary compartment. External compression straps stabilise the user\'s load and we also see that some bag designs include water bottle and/or umbrella compartments to securely store those items.

Think about how you are able to do two jobs in one with your bag, and understand that without all of the accessories, you can do both jobs at the same time while having less clutter on the inside and being able to speed through the security checkpoint.

This bag has also been designed to address the many different needs of travellers who travel for work frequently. It is typically very flexible to use, and most likely will function as a carry-on for air travel, a weekender bag for road travel, and a professional briefcase to use on trips to a client\'s office. Because the aesthetic of the bag is usually a sleek and professional-looking bag, it allows the user to utilise the same bag for both business functions and recreational activities. The versatility of the bag\'s form factor allows the user to travel with fewer bags and helps create a \"minimalist\" approach and packing method.

Even simple details, such as the low-profile luggage sleeves, provide flexibility for travellers whose bags can be slid securely over the handle of rolling luggage, thereby creating one seamless travelling unit. With tough, smooth-rolling wheels (for roller-type bags) and multiple carrying options (i.e. backpack, shoulder, or hand-carry), users can select how to carry their bag based on how they will travel. All of the above-listed attributes firmly establish this bag as not only a tool designed for one specific type of trip but also a dependable companion that meets the user\'s constantly changing demands as they travel through their lives. The design concept behind the bag is that the best travel products adapt to the needs of the traveller, rather than the traveller adapting to the product, thereby making every journey--whether for business or personal--less difficult and more enjoyable.

Laser Welding Equipment: Easily Weld Workpieces of Different Materials and Thicknesses

The Art of Comfort: Fabric and Fit

A Canvas for Expression: Bold Graphic Design and Digital Print

Genderless Style: An Essential for Men and Women

The Urban Fashion Ecosystem: Versatility and Styling

Can Laser Welding Machines Perform Automatic Seam Tracking During Welding?

Popular Blogs

-

Looking to outfit your fishing team, stock your retail store with unique apparel, or create branded merchandise for your fishing-related business? Designing your own custom fishing hoodies and shirts offers a powerful way to build brand loyalty, promote your business, and provide your customers with high-quality, comfortable apparel. This opportunity is further enhanced by the availability of wholesale pricing and bulk discounts, making it a financially viable option for businesses of all sizes. This comprehensive guide will explore the numerous benefits and considerations involved in designing and purchasing custom fishing apparel wholesale.

Looking to outfit your fishing team, stock your retail store with unique apparel, or create branded merchandise for your fishing-related business? Designing your own custom fishing hoodies and shirts offers a powerful way to build brand loyalty, promote your business, and provide your customers with high-quality, comfortable apparel. This opportunity is further enhanced by the availability of wholesale pricing and bulk discounts, making it a financially viable option for businesses of all sizes. This comprehensive guide will explore the numerous benefits and considerations involved in designing and purchasing custom fishing apparel wholesale.The Appeal of Custom Fishing Apparel

The fishing community is passionate and dedicated. Providing them with apparel that reflects their shared love of the sport fosters a sense of belonging and strengthens brand association. Custom designs allow for unparalleled creativity. Imagine hoodies emblazoned with your company logo, witty fishing puns, or stunning depictions of popular fish species. Shirts can showcase vibrant artwork, team names, or even individual angler's nicknames. This personalized touch transforms clothing into a powerful marketing tool and a cherished item for fishing enthusiasts.

Furthermore, the quality of the apparel itself is crucial. Choosing high-quality materials, like durable cotton blends for shirts and thick, comfortable fleece for hoodies, ensures customer satisfaction and longevity. This translates to positive word-of-mouth marketing and returning customers who appreciate the quality of your branded merchandise. Investing in premium materials reflects positively on your brand, projecting an image of professionalism and commitment to quality.

Wholesale Pricing and Bulk Discounts: A Cost-Effective Solution

One of the most significant advantages of designing custom fishing apparel is the potential for cost savings through wholesale pricing and bulk discounts. Purchasing in bulk significantly reduces the per-unit cost, making it a much more affordable option than buying individual items at retail prices. This is particularly beneficial for retailers looking to stock their shelves or businesses distributing branded apparel to employees or clients.

Many suppliers offer tiered pricing, where the cost per item decreases as the order quantity increases. This allows businesses to tailor their order size to their budget and anticipated demand. Understanding these pricing structures is vital to maximizing your return on investment. Carefully analyzing sales projections and comparing pricing from different suppliers will help you determine the most cost-effective order quantity.

Beyond the direct cost savings, wholesale purchasing also reduces the administrative burden associated with managing smaller, more frequent orders. This allows businesses to focus on other aspects of their operations, increasing efficiency and productivity.

Design Options and Customization Capabilities

The design possibilities are virtually limitless when it comes to custom fishing apparel. From simple logo placements to intricate all-over prints, the level of customization is dictated by your creative vision and the capabilities of your chosen supplier. High-quality printing techniques, such as screen printing, direct-to-garment printing, and embroidery, offer diverse options for achieving your desired look and feel.

Consider the target audience when choosing your design. A youthful, energetic brand might favor bold colors and modern graphics, while a more established brand might opt for a classic, understated design. The color scheme, font selection, and overall aesthetic should align with your brand identity and resonate with your target market. Working closely with your apparel supplier to discuss design options and feasibility is crucial to achieving your vision.

Don't overlook the potential of adding unique details, like custom labels or tags, to further personalize your apparel and enhance the brand experience. These small touches can elevate the perceived value of your product and create a memorable impression on your customers.

Choosing a Reliable Supplier

Selecting a reputable supplier is paramount to the success of your custom apparel project. Research different suppliers thoroughly, comparing their pricing, production times, minimum order quantities, and customer reviews. Look for suppliers who offer a wide range of customization options, high-quality materials, and excellent customer service.

Request samples of their work to assess the quality of their printing and the feel of the garments. This will give you a tangible understanding of the product you'll be receiving and help you make an informed decision. Inquire about their production process and lead times to ensure they can meet your deadlines.

Transparency and communication are essential qualities in a reliable supplier. A reputable supplier will be upfront about their pricing, production timelines, and any potential challenges. They should also be responsive to your inquiries and provide regular updates throughout the production process.

Marketing and Sales Strategies

Once your custom fishing apparel is ready, developing a robust marketing and sales strategy is crucial to maximizing its impact. Utilize social media platforms, online marketplaces, and your website to showcase your products. High-quality product photography and compelling descriptions are key to attracting potential customers.

Collaborating with fishing influencers or bloggers can provide valuable exposure and build credibility within the fishing community. Consider offering special promotions or discounts to incentivize purchases and build brand loyalty. Participating in fishing events or trade shows can offer excellent opportunities for direct sales and brand exposure.

Regularly monitor customer feedback and adapt your marketing strategies as needed. Addressing customer concerns promptly and demonstrating a commitment to quality will build trust and encourage repeat business. Custom fishing apparel is more than just clothing; it's a powerful tool for building brand awareness, fostering community, and driving sales.

dgruisha2025-01-03 -

Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women

Discover Wholesale Custom Wetsuits Diving Suits Stylish Designs for Men Women offers a unique opportunity to delve into the world of personalized aquatic gear. Forget generic, off-the-shelf wetsuits that compromise comfort and performance. This platform allows you to design and order custom-made wetsuits tailored precisely to your body, activity, and style preferences. Whether you're a seasoned diver, a passionate surfer, or simply someone who enjoys water sports, the ability to customize your wetsuit ensures an unparalleled level of fit, function, and aesthetic appeal. This opens doors to enhanced performance, increased comfort, and a truly unique expression of your individual style. This article explores the various facets of this exciting opportunity, from design options to material selection and the benefits of choosing custom over standard wetsuits.Unleashing Design Potential: A World of Customization