All Categories

-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

Safety

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

Security

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

Beauty

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

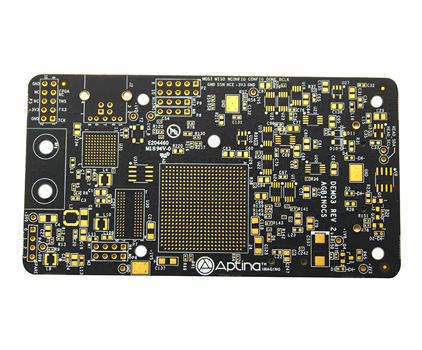

Aluminum PCB Substrate High Performance

szshuoqiang

2025-05-10

Description: Within most high performance applications where FR4 has been used historically, aluminum PCB substrates are fast gaining the mantle of choice for FR4 paper dressnorth face. Such a demand is prompted for smaller, faster, and more power-efficient electronicdevices and it contributes to this transformation. These materials are transforming industries through their ability to serve as substrates with high thermal conductivity, yield excellent mechanical strength and deliver EMI shieldingproperties in applications from aerospace and automotive to telecommunications and high-speed computing. In this exploration that follows, some ofthe main advantages of aluminum PCB substrates and their performance characteristics will be considered. Superior Thermal Management

That is why aluminum PCB substrates are among the best thermal management solution. The thermal conductivity of aluminum is multiple times higher than that of FR4, which enablesrapidly pull away heat generated on high-power elements. This works against them to prevent them from getting hot, make them more reliable, and increases their life cycle. This characteristic is essential for high-power applications, such as power supplies and electric-vehicle inverters since it allows for a higher power density along with improved efficiency.

More efficient thermalmanagement means smaller and less expensive heat sinks, which also helps with the form factor. This is particularly advantageous in space-constrained applications such as in smartphones, tablets, and wearable devices where heat dissipation is a major design challenge. Further, since heat management is spread across the entire substrate, there are no hot spots, which may cause localized failure of components, and ensures uniform performance.

Enhancement in Mechanical Strength/Stability

Compared to FR4, Aluminum PCB substrateshave much better mechanical strength and rigidity. This is especially vital for applications that need to resist vibration or shock, likeis true in aerospace or automotive or industrial control systems. The addedstability reduces the likelihood of PCB warpage or bending, which may affect circuit connections, thus improving the overall reliability of the device.

This increased mechanical strength allows thinner and lighter PCBs to be designed without compromising structural integrity. This becomes highly imperative for portable and mobileapplications due to focus on weight and size. The rigid aluminum substrate minimizes componentstress, enhances longevity and reduces the risk of worksurfacel fatigue.

Grinding Mode for Efficiency EMIShielding

Another characteristic of aluminum is that, it naturally provides decent EMI shielding, i.e., it reduces unwantedinterferenceand helps improve the signal integrity of your electronics. For example, results for high-speed data transmission and medicaldevices can not afford electromagnetic interferencein practical applications. They have a good shielding effect to impede the loss of signals, which can improve the overall performance of sensitive electronic equipment due to aluminum substrates.

Also, EMI isreduced too and that means, components can be placed closer together on the board making it easier and constraining layout, making you not just free space but also compact. Which is really useful for tighter packed circuitry that need lowelectromagnetic interference to function properly. The aluminum substrate can also work with a cover, acting as a shield barrier against electomagnetic interference(EMI) to reduce the additional EMI shielding solutions, resulting in cost and design simplification benefits.

Enhanced High Frequency Signal Integrity

The adoption of aluminum substrates has low dielectric constant and low dissipation factor, which greatly enhances the signal integrity high frequency. Thisvery important for the digital fast applications, where the signal propagation time & signal reflectionguidance is a lotmorewhat can beproblematic. Higher value of signal loss leads to the less data corrupted and hence you can achieve a greater data rate.

This leads to improved signal integrity and lower EMI enabling better performance and reliability in high-speed digital circuits. Due to high durability coefficients, the aluminum PCBsubstrates find applications in high speed data acquisition systems, in wireless communication systems and advanced computing architectures where signal integrity must bemaintained, with very little degradation of the er and rs thus makingit a very suitable candidate for such applications.

D:APPLICATION IN HIGH FREQUENCIES In conclusion, all aluminum PCB substrates offer advantages like high thermal conductivity and a higher mechanical stiffness, EMI shielding and higher signal integrity at RF and high frequencies. For these reasons, they are increasingly used in highperformanceapplications that demand reliability, efficiency andperformance. Aluminum PCB substrates will boost innovation in various industries due to continuing technology development which will further help in expanding the adoption of aluminum PCB substrates.

That is why aluminum PCB substrates are among the best thermal management solution. The thermal conductivity of aluminum is multiple times higher than that of FR4, which enablesrapidly pull away heat generated on high-power elements. This works against them to prevent them from getting hot, make them more reliable, and increases their life cycle. This characteristic is essential for high-power applications, such as power supplies and electric-vehicle inverters since it allows for a higher power density along with improved efficiency.

More efficient thermalmanagement means smaller and less expensive heat sinks, which also helps with the form factor. This is particularly advantageous in space-constrained applications such as in smartphones, tablets, and wearable devices where heat dissipation is a major design challenge. Further, since heat management is spread across the entire substrate, there are no hot spots, which may cause localized failure of components, and ensures uniform performance.

Enhancement in Mechanical Strength/Stability

Compared to FR4, Aluminum PCB substrateshave much better mechanical strength and rigidity. This is especially vital for applications that need to resist vibration or shock, likeis true in aerospace or automotive or industrial control systems. The addedstability reduces the likelihood of PCB warpage or bending, which may affect circuit connections, thus improving the overall reliability of the device.

This increased mechanical strength allows thinner and lighter PCBs to be designed without compromising structural integrity. This becomes highly imperative for portable and mobileapplications due to focus on weight and size. The rigid aluminum substrate minimizes componentstress, enhances longevity and reduces the risk of worksurfacel fatigue.

Grinding Mode for Efficiency EMIShielding

Another characteristic of aluminum is that, it naturally provides decent EMI shielding, i.e., it reduces unwantedinterferenceand helps improve the signal integrity of your electronics. For example, results for high-speed data transmission and medicaldevices can not afford electromagnetic interferencein practical applications. They have a good shielding effect to impede the loss of signals, which can improve the overall performance of sensitive electronic equipment due to aluminum substrates.

Also, EMI isreduced too and that means, components can be placed closer together on the board making it easier and constraining layout, making you not just free space but also compact. Which is really useful for tighter packed circuitry that need lowelectromagnetic interference to function properly. The aluminum substrate can also work with a cover, acting as a shield barrier against electomagnetic interference(EMI) to reduce the additional EMI shielding solutions, resulting in cost and design simplification benefits.

Enhanced High Frequency Signal Integrity

The adoption of aluminum substrates has low dielectric constant and low dissipation factor, which greatly enhances the signal integrity high frequency. Thisvery important for the digital fast applications, where the signal propagation time & signal reflectionguidance is a lotmorewhat can beproblematic. Higher value of signal loss leads to the less data corrupted and hence you can achieve a greater data rate.

This leads to improved signal integrity and lower EMI enabling better performance and reliability in high-speed digital circuits. Due to high durability coefficients, the aluminum PCBsubstrates find applications in high speed data acquisition systems, in wireless communication systems and advanced computing architectures where signal integrity must bemaintained, with very little degradation of the er and rs thus makingit a very suitable candidate for such applications.

D:APPLICATION IN HIGH FREQUENCIES In conclusion, all aluminum PCB substrates offer advantages like high thermal conductivity and a higher mechanical stiffness, EMI shielding and higher signal integrity at RF and high frequencies. For these reasons, they are increasingly used in highperformanceapplications that demand reliability, efficiency andperformance. Aluminum PCB substrates will boost innovation in various industries due to continuing technology development which will further help in expanding the adoption of aluminum PCB substrates.

REPORT