All Categories

-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

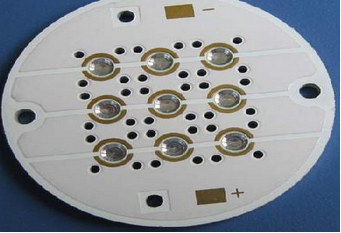

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

Safety

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

Security

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

Beauty

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

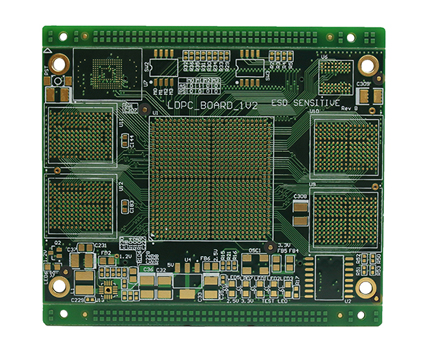

High-frequency High-speed PCB Manufacturer for 5G Base Stations

szshuoqiang

2025-05-10

With the popularity of 5G technology, High-frequency High-speed PCBs has progressively become the core \\"nerve center\\" of 5G base station. But with signal loss, ultra-precision impedance tuning, and an unparalleled test of environmental and environmental tolerance in millimeter-wave bands above 28GHz, it is tackling material, manufacturing process and quality management points like never before. A specialized manufacturer 深耕 (deeply rooted) in the communication electronics field, we offer global end-to-end solutions for 5G base station construction through technological innovation and capacity deployment.

I. High-frequency High-speed PCBs: The Silicon Foundation of 5G Base Stations

The three pledges of 5G base stations (high speed (10Gbps+), low latency (less than 1ms) and massive connectivity (millions of devices/km²)) come from the signal integrity, which is the main premise for the high frequency high-speed PCB. There are two axes of technical challenges here:

1. Blurring the Lines Between Sexiness And Safety

Ultra-Low Loss SubstratesPTFE (Polytetrafluoroethylene) composite materials (dielectric constant Dk=2.1·60±0.05, dissipation factor Df<0.0005), signal attenuation reduced over that of 40% in conventional FR-4 (Dk=4.2, Df=0.02), <0.5dB loss per inch 28GHz

High-Temperature Stability & Reliability: In Huawei\\\'s 5G base station PA modules, the BT resin substrate (temperature resistance to 220℃, CTE=13ppm/℃) ensures that the impedance remains stable within ±3% over a temperature range of -40℃ to 85℃, perfectly solving the thermal expansion/contraction-induced signal distortion.

2. Process innovation in the manufacturing process

Laser Drilling & Blind/Buried Via technology: 16-layer HDI boards utilize 355nm UV laser drilling (100μm hole diameter, ±5μm positioning accuracy) and second-order blind/buried via processes to minimize signal path lengths by 40% while maximizing in-board wiring density by 30%.

Standardized ±5% impedance control could be achieved by Ansys HFSS, while we get the accuracy of ±2% at 10GHz (industry standard); thus, conjugate matching of 50Ω/75Ω characteristic impedance is realized to reduce signal reflection and crosstalk.

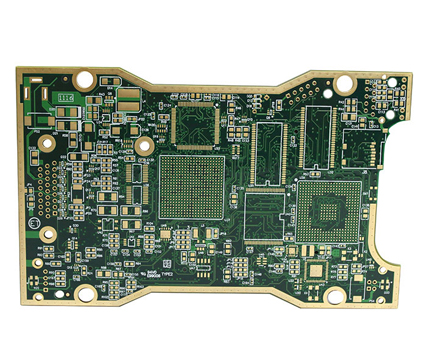

II. Tailored Solutions: End-to-End Partnership From Design → Delivery

We have established a vertically integrated closed loop on the model of \\\"requirement definition-joint R&D-mass production\\\" as a critical funnel connecting material suppliers and equipment manufacturers:

1. Technical Alignment Prior To Designing

Signal integrity simulation: The thickness of dielectric layer (typical 0.127mm) and copper foil roughness (Rz&<1.5μm) are optimized within full 3D simulation using SI9000 on Massive MIMO antenna array boards, insertion loss reduced by 20%.

Thermal Management Design: In the design of the AAU (Active Antenna Unit) PCB, a micro-channel cooling structure is embedded, the copper foil is 3oz (80A current capacity), and the temperature rise of the module can be controlled within 15℃ for outdoor long-term high-load operation;

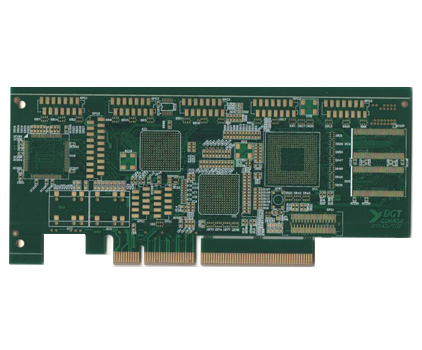

2. Intelligent Manufacturing Capabilities

Digital Production Lines: Implement ASM fully automatic placing machines (±5μm precision) and German Manz laser cutters (500mm/s speed) enabling 24-hour rapid prototyping and cut down lead time at small-to-medium batches to 7-10 days.

End-to-End Quality Control: AOI inspection (10μm resolution), X-Ray layer shift measurement (±25μm accuracy), and SATA III signal testing (6Gbps speed) together achieves the stable 98.5% yiled which is 3% higher than the industry average.

3. Global Delivery Network

We have 2 manufacturing bases with Shenzhen and Suzhou respectively (500,000㎡/month in total) as well as a warehouse in Southeast Asia, which allows us to implement fast logistics coverage, covering North America within 3-5 days, Europe 5-7 days, and APAC 2-3 days, significantly lowering customer supply chain costs.

III. INSIGHTS: Deep Empowerment for Leading OEMs and Emerging Markets

1. RELEVANT EXPERIENCE & CLIENTS TO DATE

Huawei 5G Macro Base StationsMass-supplied 20-layer PTFE composite PCBs for Sub-6GHz BBU (Baseband Unit), supports signal synchronization for 256TR massive antenna arrays (Another Global First)Enabling Huawei to deploy over 1.5 million 5G base stations globally.

Design Solution: Customized 12-layer HDI boards based on embedded capacitor technology (±5% capacitance accuracy), suppressing high-frequency noise and enabling stable transmission in 200MHz channel bandwidth for mmWave micro base stations by Nokia mmWave Equipment

2. Emerging Market Expansion

For these accelerating 5G construction regions such as India and Middle East, we provide low cost solutions: (1) asynchronous modified PPO materials (Dk=3.0, 40% lower cost than PTFE) meet Sub-6GHz performance requirement thus allowing local operators to control the single-station PCB within $2000; (2) using low cost Dk=3.0 substrate to decompose the PCB of GRX and RE based on our simulation results, it reduce the cost of single-station PCB within $2000.

IV. Raising Confidence and Acceptance of Technology for 6G

With 6G R&D in the pre-commercial stage (frequency target 100GHz+), we are developing forward-looking technologies:

Material R&D: Working with Dow Chem for aerogel substrates (Dk=1.8), samples to be evaluated in 2025;

Process Improvements: $16 million for a 12μm line/space high-order HDI production line; Supports integration of 3D packaging substrate;

Green Manufacturing: Our electroplating is 100% lead-free (Sn-Ag-Cu alloy), complete with low VOC water-based solder masks (90% lower VOC emissions), pass muster under the EU RoHS 3.0 & China continuous inspection of electronic products, EIPCCM.

Conclusion: Delivering Value for the 5G/6G Together

The high-frequency high-speed PCBs (printed circuit boards) development evolution has always undergone the upgrade transformation along with the communication standards update, from 4G to 5G, and Sub-6GHz to millimeter waves. As an industry-focused manufacturer, we are not simply a vendor for circuit boards, but we aim to be your customers\\\' \\\"technology partners. Digital Solutions Digitization is the Key. We enable next-generation communication infrastructure through continuous R&D investment (8% of annual revenue), strict quality control and global service networks. We provide solutions from material selection to mass production whether you are an equipment manufacturer, system integrator, or new market pioneer.

Get in touch with us today to access high-performance PCB technology for 5G base stations and get ready for the endless possibilities of the 6G.

I. High-frequency High-speed PCBs: The Silicon Foundation of 5G Base Stations

The three pledges of 5G base stations (high speed (10Gbps+), low latency (less than 1ms) and massive connectivity (millions of devices/km²)) come from the signal integrity, which is the main premise for the high frequency high-speed PCB. There are two axes of technical challenges here:

1. Blurring the Lines Between Sexiness And Safety

Ultra-Low Loss SubstratesPTFE (Polytetrafluoroethylene) composite materials (dielectric constant Dk=2.1·60±0.05, dissipation factor Df<0.0005), signal attenuation reduced over that of 40% in conventional FR-4 (Dk=4.2, Df=0.02), <0.5dB loss per inch 28GHz

High-Temperature Stability & Reliability: In Huawei\\\'s 5G base station PA modules, the BT resin substrate (temperature resistance to 220℃, CTE=13ppm/℃) ensures that the impedance remains stable within ±3% over a temperature range of -40℃ to 85℃, perfectly solving the thermal expansion/contraction-induced signal distortion.

2. Process innovation in the manufacturing process

Laser Drilling & Blind/Buried Via technology: 16-layer HDI boards utilize 355nm UV laser drilling (100μm hole diameter, ±5μm positioning accuracy) and second-order blind/buried via processes to minimize signal path lengths by 40% while maximizing in-board wiring density by 30%.

Standardized ±5% impedance control could be achieved by Ansys HFSS, while we get the accuracy of ±2% at 10GHz (industry standard); thus, conjugate matching of 50Ω/75Ω characteristic impedance is realized to reduce signal reflection and crosstalk.

II. Tailored Solutions: End-to-End Partnership From Design → Delivery

We have established a vertically integrated closed loop on the model of \\\"requirement definition-joint R&D-mass production\\\" as a critical funnel connecting material suppliers and equipment manufacturers:

1. Technical Alignment Prior To Designing

Signal integrity simulation: The thickness of dielectric layer (typical 0.127mm) and copper foil roughness (Rz&<1.5μm) are optimized within full 3D simulation using SI9000 on Massive MIMO antenna array boards, insertion loss reduced by 20%.

Thermal Management Design: In the design of the AAU (Active Antenna Unit) PCB, a micro-channel cooling structure is embedded, the copper foil is 3oz (80A current capacity), and the temperature rise of the module can be controlled within 15℃ for outdoor long-term high-load operation;

2. Intelligent Manufacturing Capabilities

Digital Production Lines: Implement ASM fully automatic placing machines (±5μm precision) and German Manz laser cutters (500mm/s speed) enabling 24-hour rapid prototyping and cut down lead time at small-to-medium batches to 7-10 days.

End-to-End Quality Control: AOI inspection (10μm resolution), X-Ray layer shift measurement (±25μm accuracy), and SATA III signal testing (6Gbps speed) together achieves the stable 98.5% yiled which is 3% higher than the industry average.

3. Global Delivery Network

We have 2 manufacturing bases with Shenzhen and Suzhou respectively (500,000㎡/month in total) as well as a warehouse in Southeast Asia, which allows us to implement fast logistics coverage, covering North America within 3-5 days, Europe 5-7 days, and APAC 2-3 days, significantly lowering customer supply chain costs.

III. INSIGHTS: Deep Empowerment for Leading OEMs and Emerging Markets

1. RELEVANT EXPERIENCE & CLIENTS TO DATE

Huawei 5G Macro Base StationsMass-supplied 20-layer PTFE composite PCBs for Sub-6GHz BBU (Baseband Unit), supports signal synchronization for 256TR massive antenna arrays (Another Global First)Enabling Huawei to deploy over 1.5 million 5G base stations globally.

Design Solution: Customized 12-layer HDI boards based on embedded capacitor technology (±5% capacitance accuracy), suppressing high-frequency noise and enabling stable transmission in 200MHz channel bandwidth for mmWave micro base stations by Nokia mmWave Equipment

2. Emerging Market Expansion

For these accelerating 5G construction regions such as India and Middle East, we provide low cost solutions: (1) asynchronous modified PPO materials (Dk=3.0, 40% lower cost than PTFE) meet Sub-6GHz performance requirement thus allowing local operators to control the single-station PCB within $2000; (2) using low cost Dk=3.0 substrate to decompose the PCB of GRX and RE based on our simulation results, it reduce the cost of single-station PCB within $2000.

IV. Raising Confidence and Acceptance of Technology for 6G

With 6G R&D in the pre-commercial stage (frequency target 100GHz+), we are developing forward-looking technologies:

Material R&D: Working with Dow Chem for aerogel substrates (Dk=1.8), samples to be evaluated in 2025;

Process Improvements: $16 million for a 12μm line/space high-order HDI production line; Supports integration of 3D packaging substrate;

Green Manufacturing: Our electroplating is 100% lead-free (Sn-Ag-Cu alloy), complete with low VOC water-based solder masks (90% lower VOC emissions), pass muster under the EU RoHS 3.0 & China continuous inspection of electronic products, EIPCCM.

Conclusion: Delivering Value for the 5G/6G Together

The high-frequency high-speed PCBs (printed circuit boards) development evolution has always undergone the upgrade transformation along with the communication standards update, from 4G to 5G, and Sub-6GHz to millimeter waves. As an industry-focused manufacturer, we are not simply a vendor for circuit boards, but we aim to be your customers\\\' \\\"technology partners. Digital Solutions Digitization is the Key. We enable next-generation communication infrastructure through continuous R&D investment (8% of annual revenue), strict quality control and global service networks. We provide solutions from material selection to mass production whether you are an equipment manufacturer, system integrator, or new market pioneer.

Get in touch with us today to access high-performance PCB technology for 5G base stations and get ready for the endless possibilities of the 6G.

REPORT