-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

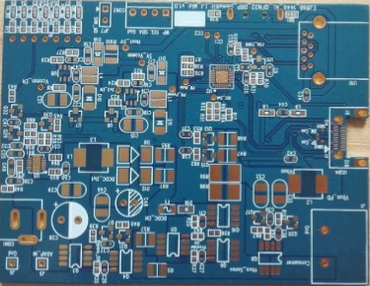

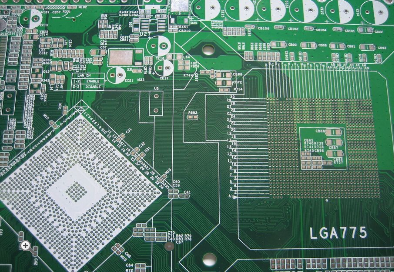

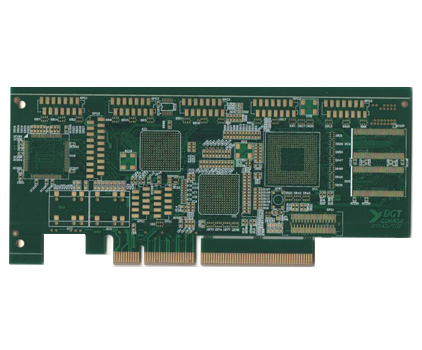

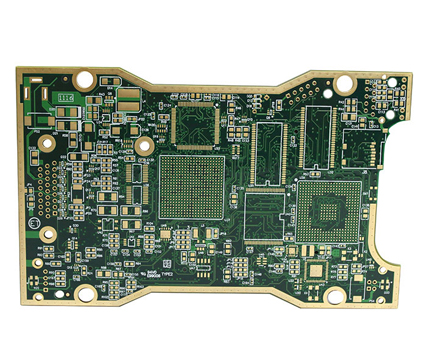

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

Advanced Impedance Analysis in PCB Manufacturing Tools and Methods for Testing and Verifying Impedance Accuracy in Production

In the rapidly evolving landscape of electronics, the demand for high-speed, high-frequency printed circuit boards (PCBs) has never been greater. From 5G infrastructure and advanced computing to automotive radar and IoT devices, signal integrity is paramount. At the heart of this integrity lies controlled impedance—a precise electrical characteristic that ensures signals travel without distortion, reflection, or loss. As data rates soar into the multi-gigabit range, even minor deviations in impedance can lead to catastrophic system failures, making its accurate verification a critical bottleneck in production. This brings us to the sophisticated domain of Advanced Impedance Analysis in PCB Manufacturing. This article delves into the cutting-edge tools and rigorous methodologies employed to test and verify impedance accuracy directly on the production floor, moving beyond design simulation to ensure every board meets its exacting electrical specifications. We will explore how modern manufacturing confronts this challenge, balancing precision with throughput to deliver reliable, high-performance electronics.

The Imperative of In-Line and At-Speed Testing Methodologies

Traditional impedance verification often relied on coupon testing—measuring dedicated test structures on the panel periphery—or on benchtop equipment requiring extensive manual setup. While valuable, these methods are inherently destructive, sample-based, and cannot guarantee the impedance of every production board. Advanced analysis now prioritizes non-destructive, in-line testing capable of measuring the actual traces on the functional PCB. Time Domain Reflectometry (TDR) remains a cornerstone technology for this purpose. A modern, high-bandwidth TDR system sends a fast-edge step signal down a trace and analyzes the reflected waveform. The impedance profile along the trace's length is derived from this reflection, revealing not just an average value but localized imperfections like variations caused by etching defects, material inconsistencies, or via transitions.

Complementing TDR, Vector Network Analyzer (VNA)-based methods are crucial for frequency-domain characterization, especially for very high-frequency designs. VNAs measure scattering parameters (S-parameters), providing a comprehensive view of how the interconnect behaves across a wide frequency spectrum. This is essential for understanding insertion loss, return loss, and crosstalk, all of which are directly influenced by impedance control. The trend is toward integrating these capabilities into automated test equipment (ATE) or flying probe testers, enabling 100% impedance verification on critical nets as part of the standard electrical test flow. This shift from off-line lab analysis to integrated production testing is fundamental to achieving the required quality assurance for high-volume, high-reliability products.

Advanced Tools: From High-Precision Instruments to Integrated Systems

The toolset for advanced impedance analysis is specialized and evolving. High-performance TDR oscilloscopes with bandwidths exceeding 20 GHz are now standard for analyzing signals with rise times below 20 picoseconds. These instruments feature sophisticated calibration routines to de-embed the effects of probes and fixtures, ensuring the measurement is of the Device Under Test (DUT) itself. Equally important are the probing solutions. High-frequency, ground-signal-ground (GSG) or coaxial probes provide a controlled impedance path from the instrument to the PCB test point, minimizing parasitic effects that could skew results. For production environments, bespoke test fixtures with integrated calibration standards and spring-loaded pogo pins allow for rapid, repeatable connections to board test pads.

Beyond standalone instruments, the integration of impedance measurement into broader data acquisition systems is a key advancement. Software plays a pivotal role here. Advanced analysis platforms can import PCB design data (e.g., Gerber, ODB++), automatically generate test programs, and compare real-time TDR or VNA measurements directly against the design's impedance targets. They can create color-coded maps of the board, highlighting traces that pass or fail with statistical process control (SPC) data. This closed-loop feedback between design, measurement, and manufacturing is critical for root-cause analysis and continuous process improvement, allowing engineers to quickly identify whether an impedance fault stems from laminate material drift, lamination pressure, or line width/space etching issues.

Overcoming Production Challenges: Fixturing, Calibration, and Process Control

Implementing robust impedance verification in a production setting presents unique challenges. The first is fixturing and access. Test points must be designed into the board, balancing measurement needs with real estate constraints. Fixtures must be mechanically robust for thousands of cycles while maintaining electrical performance. Thermal management is also critical, as the dielectric constant (Dk) of PCB materials is temperature-sensitive; measurements must be taken under controlled conditions or compensated accordingly. Calibration is non-negotiable. A rigorous calibration sequence, using standards traceable to national institutes, must be performed daily or per shift to eliminate systematic errors from cables, probes, and the instrument itself. This often involves a full Short-Open-Load-Thru (SOLT) or Through-Reflect-Line (TRL) calibration at the probe tips.

The ultimate goal is to move from simple pass/fail testing to predictive process control. By collecting impedance data from every board over time, manufacturers can build a rich statistical database. Using SPC charts, they can monitor trends—such as a gradual increase in impedance due to lithography tool wear or a decrease linked to prepreg resin content variation—and intervene before the process drifts out of specification. This proactive approach minimizes scrap, improves yield, and provides tangible data for qualifying new material sets or process changes. It transforms impedance from a final inspection checkpoint into a controlled, monitored, and optimized manufacturing parameter.

The Future: Towards Embedded Sensors and AI-Driven Analysis

The frontier of impedance analysis lies in even greater integration and intelligence. Research is ongoing into embedded sensors within the PCB laminate that could provide real-time, in-situ monitoring of dielectric properties during the lamination process itself. Furthermore, the vast datasets generated by 100% impedance testing are ripe for analysis by machine learning (ML) and artificial intelligence (AI) algorithms. These systems could learn complex patterns, predicting final impedance based on upstream process parameters like copper plating thickness or etch rates, enabling true predictive quality control.

Another direction is the standardization of test methods and data formats across the industry to facilitate smoother communication between designers, fabricators, and assemblers. As the line between PCB, package, and silicon blurs with advanced packaging (e.g., fan-out wafer-level packaging), impedance analysis tools must adapt to characterize these 3D interconnects. The journey of advanced impedance analysis is one of constant adaptation, driven by the unrelenting push for faster, smaller, and more reliable electronics, ensuring that the physical board faithfully executes the designer's intent in the final product.

REPORT