-

Agriculture

Agriculture

-

Health-Care

Health-Care

-

Environment

Environment

-

Construction-Real-Estate

Construction-Real-Estate

-

Tools-Hardware

Tools-Hardware

-

Home-Garden

Home-Garden

-

Furniture

Furniture

-

Luggage-Bags-Cases

Luggage-Bags-Cases

-

Medical-devices-Supplies

Medical-devices-Supplies

-

Gifts-Crafts

Gifts-Crafts

-

Sports-Entertainment

Sports-Entertainment

-

Food-Beverage

Food-Beverage

-

Vehicles-Transportation

Vehicles-Transportation

-

Power-Transmission

Power-Transmission

-

Material-Handling

Material-Handling

-

Renewable-Energy

Renewable-Energy

-

Safety

Safety

-

Testing-Instrument-Equipment

Testing-Instrument-Equipment

-

Construction-Building-Machinery

Construction-Building-Machinery

-

Pet-Supplies

Pet-Supplies

-

Personal-Care-Household-Cleaning

Personal-Care-Household-Cleaning

-

Vehicle-Accessories-Electronics-Tools

Vehicle-Accessories-Electronics-Tools

-

School-Office-Supplies

School-Office-Supplies

-

Packaging-Printing

Packaging-Printing

-

Mother-Kids-Toys

Mother-Kids-Toys

-

Business-Services

Business-Services

-

Commercial-Equipment-Machinery

Commercial-Equipment-Machinery

-

Apparel-Accessories

Apparel-Accessories

-

Security

Security

-

Shoes-Accessories

Shoes-Accessories

-

Vehicle-Parts-Accessories

Vehicle-Parts-Accessories

-

Jewelry-Eyewear-Watches-Accessories

Jewelry-Eyewear-Watches-Accessories

-

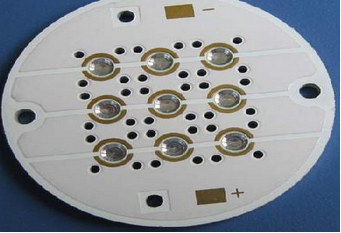

Lights-Lighting

Lights-Lighting

-

Fabric-Textile-Raw-Material

Fabric-Textile-Raw-Material

-

Fabrication-Services

Fabrication-Services

-

Industrial-Machinery

Industrial-Machinery

-

Consumer-Electronics

Consumer-Electronics

-

Electrical-Equipment-Supplies

Electrical-Equipment-Supplies

-

Electronic-Components-Accessories-Telecommunications

Electronic-Components-Accessories-Telecommunications

-

Home-Appliances

Home-Appliances

-

Beauty

Beauty

-

Chemicals

Chemicals

-

Rubber-Plastics

Rubber-Plastics

-

Metals-Alloys

Metals-Alloys

- Masonry Materials

- Curtain Walls & Accessories

- Earthwork Products

- Fireproofing Materials

- Heat Insulation Materials

- Plastic Building Materials

- Building Boards

- Soundproofing Materials

- Timber

- Waterproofing Materials

- Balustrades & Handrails

- Bathroom & Kitchen

- Flooring & Accessories

- Tiles & Accessories

- Door, Window & Accessories

- Fireplaces & Stoves

- Floor Heating Systems & Parts

- Stairs & Stair Parts

- Ceilings

- Elevators & Escalators

- Stone

- Countertops, Vanity Tops & Table Tops

- Mosaics

- Metal Building Materials

- Multifunctional Materials

- Ladders & Scaffoldings

- Mouldings

- Corner Guards

- Decorative Films

- Formwork

- Building & Industrial Glass

- Other Construction & Real Estate

- Wallpapers/Wall panels

- HVAC System & Parts

- Outdoor Facilities

- Prefabricated Buildings

- Festive & Party Supplies

- Bathroom Products

- Household Sundries

- Rain Gear

- Garden Supplies

- Household Cleaning Tools & Accessories

- Lighters & Smoking Accessories

- Home Storage & Organization

- Household Scales

- Smart Home Improvement

- Home Textiles

- Kitchenware

- Drinkware & Accessories

- Dinnerware, Coffee & Wine

- Home Decor

- Golf

- Fitness & Body Building

- Amusement Park Facilities

- Billiards, Board Game,Coin Operated Games

- Musical Instruments

- Outdoor Affordable Luxury Sports

- Camping & Hiking

- Fishing

- Sports Safety&Rehabilitation

- Ball Sports Equipments

- Water Sports

- Winter Sports

- Luxury Travel Equipments

- Sports Shoes, Bags & Accessories

- Cycling

- Other Sports & Entertainment Products

- Artificial Grass&Sports Flooring&Sports Court Equipment

- Scooters

- Food Ingredients

- Honey & Honey Products

- Snacks

- Nuts & Kernels

- Seafood

- Plant & Animal Oil

- Beverages

- Fruit & Vegetable Products

- Frog & Escargot

- Bean Products

- Egg Products

- Dairy Products

- Seasonings & Condiments

- Canned Food

- Instant Food

- Baked Goods

- Other Food & Beverage

- Meat & Poultry

- Confectionery

- Grain Products

- Feminie Care

- Hair Care & Styling

- Body Care

- Hands & Feet Care

- Hygiene Products

- Men's Grooming

- Laundry Cleaning Supplies

- Travel Size & Gift Sets

- Room Deodorizers

- Other Personal Care Products

- Pest Control Products

- Special Household Cleaning

- Floor Cleaning

- Kitchen & Bathroom Cleaning

- Oral Care

- Bath Supplies

- Yellow Pages

- Correction Supplies

- Office Binding Supplies

- Office Cutting Supplies

- Board Erasers

- Office Adhesives & Tapes

- Education Supplies

- Pencil Cases & Bags

- Notebooks & Writing Pads

- File Folder Accessories

- Calendars

- Writing Accessories

- Commercial Office Supplies

- Pencil Sharpeners

- Pens

- Letter Pad/Paper

- Paper Envelopes

- Desk Organizers

- Pencils

- Markers & Highlighters

- Filing Products

- Art Supplies

- Easels

- Badge Holder & Accessories

- Office Paper

- Printer Supplies

- Book Covers

- Other Office & School Supplies

- Stationery Set

- Boards

- Clipboards

- Stamps

- Drafting Supplies

- Stencils

- Electronic Dictionary

- Books

- Map

- Magazines

- Calculators

- Baby & Toddler Toys

- Educational Toys

- Classic Toys

- Dress Up & Pretend Play

- Toy Vehicle

- Stuffed Animals & Plush Toys

- Outdoor Toys & Structures

- Balloons & Accessories

- Baby Food

- Children's Clothing

- Baby Supplies & Products

- Maternity Clothes

- Kids Shoes

- Baby Care

- Novelty & Gag Toys

- Dolls & Accessories

- Puzzle & Games

- Blocks & Model Building Toys

- Toddler Clothing

- Baby Clothing

- Kids' Luggage & Bags

- Arts, Crafts & DIY Toys

- Action & Toy Figures

- Baby Appliances

- Hobbies & Models

- Remote Control Toys

- Promotional Toys

- Pregnancy & Maternity

- Hygiene Products

- Kid's Textile&Bedding

- Novelty & Special Use

- Toy Weapons

- Baby Gifts

- Baby Storage & Organization

- Auto Drive Systems

- ATV/UTV Parts & Accessories

- Marine Parts & Accessories

- Other Auto Parts

- Trailer Parts & Accessories

- Auto Transmission Systems

- Train Parts & Accessories

- Universal Parts

- Railway Parts & Accessories

- Auto Brake Systems

- Aviation Parts & Accessories

- Truck Parts & Accessories

- Auto Suspension Systems

- Auto Lighting Systems

- New Energy Vehicle Parts & Accessories

- Auto Steering Systems

- Wheels, Tires & Accessories

- Bus Parts & Accessories

- Auto Performance Parts

- Cooling System

- Go-Kart & Kart Racer Parts & Accessories

- Air Conditioning Systems

- Heavy Duty Vehicle Parts & Accessories

- Auto Electrical Systems

- Auto Body Systems

- Auto Engine Systems

- Container Parts & Accessories

- Motorcycle Parts & Accessories

- Refrigeration & Heat Exchange Equipment

- Machine Tool Equipment

- Food & Beverage Machinery

- Agricultural Machinery & Equipment

- Apparel & Textile Machinery

- Chemical Machinery

- Packaging Machines

- Paper Production Machinery

- Plastic & Rubber Processing Machinery

- Industrial Robots

- Electronic Products Machinery

- Metal & Metallurgy Machinery

- Woodworking Machinery

- Home Product Manufacturing Machinery

- Machinery Accessories

- Environmental Machinery

- Machinery Service

- Electrical Equipment Manufacturing Machinery

- Industrial Compressors & Parts

- Tobacco & Cigarette Machinery

- Production Line

- Used Industrial Machinery

- Electronics Production Machinery

- Other Machinery & Industrial Equipment

- Camera, Photo & Accessories

- Portable Audio, Video & Accessories

- Television, Home Audio, Video & Accessories

- Video Games & Accessories

- Mobile Phone & Accessories

- Electronic Publications

- Earphone & Headphone & Accessories

- Speakers & Accessories

- Smart Electronics

- TV Receivers & Accessories

- Mobile Phone & Computer Repair Parts

- Chargers, Batteries & Power Supplies

- Used Electronics

- VR, AR, MR Hardware & Software

- Projectors & Presentation Equipments

- Other Consumer Electronics

- Cables & Commonly Used Accessories

- Computer Hardware & Software

- Displays, Signage and Optoelectronics

- Discrete Semiconductors

- Wireless & IoT Module and Products

- Telecommunications

- Connectors, Terminals & Accessories

- Development Boards, Electronic Modules and Kits

- Circuit Protection

- Sensors

- Isolators

- Audio Components and Products

- Integrated Circuits

- Power Supplies

- Relays

- RF, Microwave and RFID

- Electronic Accessories & Supplies

- Passive Components

- PCB & PCBA

- Air Quality Appliances

- Home Appliance Parts

- Heating & Cooling Appliances

- Small Kitchen Appliances

- Laundry Appliances

- Water Heaters

- Water Treatment Appliances

- Refrigerators & Freezers

- Personal Care & Beauty Appliances

- Major Kitchen Appliances

- Cleaning Appliances

- Second-hand Appliances

- Smart Home Appliances

- Other Home Appliances

- Energy Chemicals

- Inorganic Chemicals

- Basic Organic Chemicals

- Agrochemicals

- Admixture & Additives

- Catalysts & Chemical Auxiliary Agents

- Pigments & Dyestuff

- Coating & Paint

- Daily Chemicals

- Polymer

- Organic Intermediate

- Adhesives & Sealants

- Chemical Waste

- Biological Chemical Products

- Surface Treatment Chemicals

- Painting & Coating

- Chemical Reagents

- Flavor & Fragrance

- Non-Explosive Demolition Agents

- Other Chemicals

- Custom Chemical Services

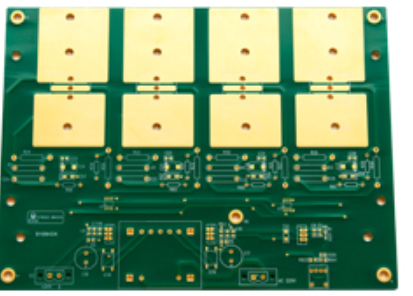

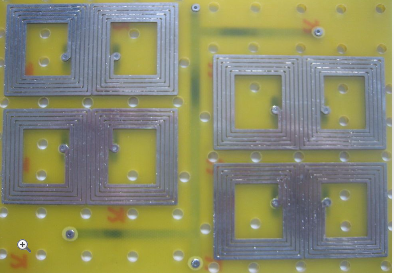

Robust Multi Layer PCB Architectures For Demanding RF Filter And Power Amplifier Applications

In the rapidly advancing landscape of wireless communication, radar systems, and satellite technology, the demand for high-performance Radio Frequency (RF) components has never been greater. At the heart of these systems lie critical elements like RF filters and power amplifiers, which must operate with exceptional precision, efficiency, and reliability under stringent conditions. Traditional printed circuit board (PCB) designs often fall short when faced with the challenges of signal integrity, thermal management, and electromagnetic interference inherent in high-frequency, high-power applications. This is where robust multi-layer PCB architectures emerge as a transformative solution. By integrating sophisticated layer stacking, advanced materials, and innovative design principles, these architectures provide the necessary foundation to meet the exacting requirements of modern RF systems. This article delves into the core aspects of these robust multi-layer designs, exploring how they enable superior performance, miniaturization, and durability for demanding RF filter and power amplifier applications, thereby pushing the boundaries of what is possible in electronic engineering.

Advanced Material Selection and Layer Stackup Configuration

The foundation of any robust multi-layer PCB for RF applications begins with the careful selection of substrate materials. Standard FR-4 materials, while cost-effective, exhibit significant dielectric losses and unstable dielectric constants at high frequencies, which can degrade signal quality. Therefore, high-frequency laminates such as Rogers RO4000 series, Taconic RF-35, or PTFE-based materials are often employed. These materials offer low dissipation factors, consistent dielectric constants over a wide frequency range, and excellent thermal stability, which is crucial for maintaining the performance of RF filters and power amplifiers.

Equally critical is the strategic configuration of the layer stackup. A typical robust architecture may consist of 8 to 12 or more layers, meticulously arranged to isolate sensitive RF signals from noisy digital or power planes. Signal layers are often embedded between ground planes to form controlled impedance stripline structures, which shield the traces from external interference and reduce crosstalk. The stackup is designed to provide dedicated layers for RF routing, DC power distribution, and a solid, unbroken ground reference. This careful planning ensures minimal signal path discontinuities, preserves signal integrity, and provides effective return paths for high-speed currents, which is paramount for the precise frequency response of filters and the linearity of power amplifiers.

Enhanced Thermal Management and Power Integrity

Power amplifiers, by their nature, dissipate substantial amounts of heat. Inadequate thermal management can lead to performance drift, reduced efficiency, and premature component failure. Robust multi-layer PCBs address this challenge through integrated thermal design. This involves incorporating thick copper planes (2 oz or more) on inner layers to spread heat laterally. Thermal vias—arrays of plated through-holes—are strategically placed directly under heat-generating components, such as power transistor packages, to create efficient vertical conduits that transfer heat from the component side to internal copper layers or dedicated thermal backing planes.

Furthermore, the architecture ensures robust power integrity. Dedicated power planes with low impedance are essential to deliver stable, ripple-free DC voltage to the power amplifier stages. This is achieved by using multiple power planes in parallel, reducing parasitic inductance. Decoupling capacitors are placed in close proximity to amplifier ICs, with their ground connections tied directly to the ground plane via short, low-inductance vias. The multi-layer approach allows for the creation of localized power islands and optimized power distribution networks (PDNs), which prevent voltage sag during high-current transients and minimize noise coupling into sensitive RF filter circuits, thereby ensuring stable amplification and clean signal filtration.

Precision RF Routing and Electromagnetic Shielding

The physical routing of RF traces is a discipline where precision is non-negotiable. In multi-layer architectures, RF signals are routed on controlled-impedance transmission lines, typically microstrip or stripline. The width and spacing of these traces are calculated with exacting precision based on the dielectric constant of the laminate and the desired impedance (commonly 50 or 75 ohms). Corners are mitered to avoid impedance discontinuities, and vias transitioning between layers are minimized and carefully modeled to prevent unwanted inductance and resonance that could distort filter responses or amplifier gain.

Electromagnetic compatibility (EMC) is a paramount concern. The multi-layer structure itself provides inherent shielding. Sensitive filter circuits, often consisting of inductors and capacitors forming resonant structures, are isolated on dedicated layers sandwiched between ground planes. This containment prevents both the emission of spurious signals and susceptibility to external noise. For critical sections, additional shielding can be implemented using "fence vias"—rows of grounded vias surrounding a circuit block—to create a Faraday cage effect. Cavity structures can also be designed within the PCB stackup to isolate components physically and electrically, a technique particularly beneficial for integrating bulk acoustic wave (BAW) or surface acoustic wave (SAW) filters alongside amplifiers in a single module.

Integration, Reliability, and Manufacturing Considerations

A key advantage of robust multi-layer architectures is the ability to achieve high levels of integration. Passive components for RF filters, such as inductors and capacitors, can be embedded within the inner layers as planar structures (embedded passives), saving surface area, reducing parasitic effects from solder joints, and improving performance repeatability. This allows for the co-design and co-packaging of filters and amplifiers into a single, compact module, which is essential for modern devices like smartphones and phased-array antennas.

Reliability under demanding environmental and operational conditions is engineered into the design. The use of high-Tg (glass transition temperature) materials and compatible plating finishes ensures the PCB can withstand the thermal cycling caused by power amplifier operation. Mechanical robustness is addressed through balanced stackups to prevent warping and by ensuring strong interlayer adhesion. From a manufacturing perspective, these designs require close collaboration between the RF designer and the PCB fabricator. Advanced processes like laser drilling for micro-vias, precise layer-to-layer registration, and stringent impedance control testing are necessary to realize the design intent faithfully, ensuring that the final product performs reliably in the field.

REPORT